Stable Micro Systems Texture Analysers are used frequently in patent applications to substantiate claims and provide measured evidence associated with the developed product. Here are a few recent examples within the field of Personal Care Products…

A patent has recently been released by Procter and Gamble, entitled ‘Skin Care Composition’.

It covers a personal care composition incorporating a dimethicone fluid for the cosmetic treatment of skin that provides an improved moisturisation signal to a user and exhibits good feel properties.

The researchers used their TA.XT2i Texture Analyser to perform a tack test on a film formed from the composition.

Read more >

Stable Micro Systems will no longer be posting to this blog, visit our new blog on our main website.

Click on banner above to go to the blog.

Thursday, 19 December 2019

Tuesday, 10 December 2019

Texture Analysis in Action: Vickers and Shore Hardness Probe

Vickers testing has been a very widely-used technique for many materials for decades due to simple data analysis and test preparation.

Many applications demand a tip made from a very hard material such as diamond or sapphire, as the indenter must be significantly harder than the material under investigation. However, stainless steel is suitable for testing many softer materials such as tablets, soap, fruit and vegetables, cheese, chocolate and some polymers.

Traditionally, Vickers hardness is calculated by inputting the indentation diagonals into a standard formula. However, instrumented indentation on a Texture Analyser allows automatic hardness analysis without the use of a microscope. It also enables other parameters such as stress relaxation and elastic-plastic energy ratios to be calculated.

Many applications demand a tip made from a very hard material such as diamond or sapphire, as the indenter must be significantly harder than the material under investigation. However, stainless steel is suitable for testing many softer materials such as tablets, soap, fruit and vegetables, cheese, chocolate and some polymers.

Traditionally, Vickers hardness is calculated by inputting the indentation diagonals into a standard formula. However, instrumented indentation on a Texture Analyser allows automatic hardness analysis without the use of a microscope. It also enables other parameters such as stress relaxation and elastic-plastic energy ratios to be calculated.

Tuesday, 3 December 2019

Texture Analysis in Research: Edible Packaging

At the grocery store, most foods — meats, breads, cheeses, snacks — come wrapped in plastic packaging.

Not only does this create a lot of non-recyclable, non-biodegradable waste, but thin plastic films are not great at preventing spoilage – and some plastics are suspected of leaching potentially harmful compounds into food.

Current food packaging is mainly petroleum-based, which is not sustainable. It also does not degrade, creating tons of plastic waste that sits in landfills for years – an issue that is now weighing heavily on the minds of all consumers after recent documentaries. To address these issues, scientists are now developing a packaging film made of milk proteins — and it is even edible.

Not only does this create a lot of non-recyclable, non-biodegradable waste, but thin plastic films are not great at preventing spoilage – and some plastics are suspected of leaching potentially harmful compounds into food.

Current food packaging is mainly petroleum-based, which is not sustainable. It also does not degrade, creating tons of plastic waste that sits in landfills for years – an issue that is now weighing heavily on the minds of all consumers after recent documentaries. To address these issues, scientists are now developing a packaging film made of milk proteins — and it is even edible.

Tuesday, 26 November 2019

Texture Analysis in Research: Medical Applications

Scientists from Nantes University Hospital have been researching standardised bench test evaluation of coronary stents and their biomechanical characteristics.

The purpose of the study was to develop a standardised and global bench test protocol to evaluate the biomechanical characteristics of the most currently used drug‐eluting coronary stents. The use of coronary stents has contributed to the reduction of cardiovascular mortality but can be associated with specific complications. Improving the biomechanical matching between the stents and the coronary anatomy may reduce these complications.

The purpose of the study was to develop a standardised and global bench test protocol to evaluate the biomechanical characteristics of the most currently used drug‐eluting coronary stents. The use of coronary stents has contributed to the reduction of cardiovascular mortality but can be associated with specific complications. Improving the biomechanical matching between the stents and the coronary anatomy may reduce these complications.

Tuesday, 19 November 2019

Texture Analysis in Action: Multi-head Indexing Probe

|

| Multi-head Indexing Probe |

This thereby allows for ‘walk-away’ time from testing due to the system being able to automatically index to a new probe after each test.

The video shown here gives an example of how the Automated Indexing System can operate with this Multi-head Indexing Probe.

Tuesday, 12 November 2019

Texture Analysis in Research: Substitution and Supplementation in Bakery Products

In the bakery industry, formulations continue to be tested that replace an ingredient (such as gluten) or supplement (e.g. soybean or soy protein) to enhance a product.

The following are recent publications highlighting the use of a texture analyser to measure the effects of such formulation change.

Scientists from Nanjing University of Finance and Economics have been researching the effects of whey and soy protein addition on the rheological properties of wheat dough.

Since it is known that the gluten network is responsible for viscoelastic properties in wheat dough and for dough structure strength and gas retention, most studies reported that enrichment of

The following are recent publications highlighting the use of a texture analyser to measure the effects of such formulation change.

Scientists from Nanjing University of Finance and Economics have been researching the effects of whey and soy protein addition on the rheological properties of wheat dough.

Since it is known that the gluten network is responsible for viscoelastic properties in wheat dough and for dough structure strength and gas retention, most studies reported that enrichment of

Tuesday, 5 November 2019

Texture Analysis in Patents: Medical Applications

Stable Micro Systems Texture Analysers are used frequently in patent applications to substantiate claims and provide measured evidence associated with the developed product. Here are a few recent examples within the field of Medicine…

A patent has recently been released by LG Household and Health Care Ltd entitled ‘Preparation for Attaching to Teeth or Surrounding Part of Teeth’.

There are many difficulties involved with delivering an active ingredient into the oral cavity as the contact time and quantity play an important role. As outlined in the patent, there are disadvantages to existing delivery methods. The new preparation delivers an active ingredient whose physical properties are changed before attachment to teeth and after a period of time after the attachment.

A patent has recently been released by LG Household and Health Care Ltd entitled ‘Preparation for Attaching to Teeth or Surrounding Part of Teeth’.

There are many difficulties involved with delivering an active ingredient into the oral cavity as the contact time and quantity play an important role. As outlined in the patent, there are disadvantages to existing delivery methods. The new preparation delivers an active ingredient whose physical properties are changed before attachment to teeth and after a period of time after the attachment.

Tuesday, 29 October 2019

Texture Analysis in Research: Cosmetic Applications

Throughout the world Stable Micro Systems Texture Analysers are being used in universities, institutes and research and development departments as a tool to measure the texture and physical properties of new products and to assist in the progression of research.

Here are several recent examples of the use of Texture Analysis in cosmetic research and product development...

Here are several recent examples of the use of Texture Analysis in cosmetic research and product development...

Tuesday, 22 October 2019

Boosting satiety in low calorie foods

According to a scientist at the Norwegian Institute of Food, Fisheries and Aquaculture (Nofima), reshaping the texture of well-liked foods could help combat obesity and over-eating.

Quoc Cuong Nguyen's research investigates the link between sensory perception, consumer expectation and satiety and finds that changing the texture of well-liked foods, to prolong the chewing time and ensure prolonged oral exposure, could make people eat less whilst experiencing a similar level of pleasure.

Quoc Cuong Nguyen's research investigates the link between sensory perception, consumer expectation and satiety and finds that changing the texture of well-liked foods, to prolong the chewing time and ensure prolonged oral exposure, could make people eat less whilst experiencing a similar level of pleasure.

Tuesday, 15 October 2019

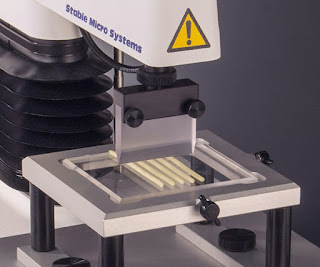

Texture Analysis in Action: New AACC Standard Pasta Blade

A new blade has been developed after extensive work carried out by a set of collaborators to improve the AACC method for cooked pasta quality/firmness measurement.

Whilst the existing blade (which is in accordance with AACC Standard method 66-50.01) will still be available, this new blade is to be used in accordance with the improved AACC standard method (66-52.01).

Whilst the existing blade (which is in accordance with AACC Standard method 66-50.01) will still be available, this new blade is to be used in accordance with the improved AACC standard method (66-52.01).

Tuesday, 8 October 2019

Texture Analysis testing Keto

The ketogenic diet is a low-carb, high fat diet that has been used historically to control seizures in some epilepsy patients, while causing the body to burn fat (rather than glucose) for energy. It has had a recent revival and become an extremely popular way to lose weight. While a person on the keto diet will not go hungry with the large choice of filling foods still available (meat, fish, eggs, cheese, butter, nuts, berries and cream to name a few), one thing they do lack is the comforting feeling of sitting down to a plate of pasta or a steaming jam sponge pudding and custard.

Tuesday, 1 October 2019

Popping Candy for Drug Delivery – Acoustic Measurement on a Texture Analyser

Popping candy, often known by various brand names, uses pressurised carbon dioxide gas trapped in a sugar matrix to cause popping noises and crackling sensations when the gas is released in the moisture and temperature of the mouth.

Popping candy, often known by various brand names, uses pressurised carbon dioxide gas trapped in a sugar matrix to cause popping noises and crackling sensations when the gas is released in the moisture and temperature of the mouth.

Popping candy was invented decades ago to be sold as confectionery. More recently, however, food manufacturers and chefs have been incorporating it into chocolate and other types of food to provide an additional point of interest. It is not only food that has benefited from the invention; the pharmaceutical industry is also becoming wise to this interesting ingredient.

Tuesday, 24 September 2019

Analysing the Physical Properties of a First Aid Kit

Texture Analysers play a large role in the quality control process of the pharmaceutical industry.

The mechanical properties of all products must be uniform between batches or customer loyalty will decline. This blog post outlines some typical measurements that may be made on the contents of a first aid kit.

Adhesive plasters are often bought as a continuous strip that can be cut to the length needed by the consumer. A measurement on the 180° Peel Test Rig can determine the comparative peeling or stripping characteristics of adhesive bonds, essential for the application of adhesive bandages. Wound dressings and adhesive strips are required to have qualities such as 'low-tack' or moisture-resistance. The plaster’s adhesive properties as are important as the selection of the strip material and surface.

The mechanical properties of all products must be uniform between batches or customer loyalty will decline. This blog post outlines some typical measurements that may be made on the contents of a first aid kit.

Adhesive plasters are often bought as a continuous strip that can be cut to the length needed by the consumer. A measurement on the 180° Peel Test Rig can determine the comparative peeling or stripping characteristics of adhesive bonds, essential for the application of adhesive bandages. Wound dressings and adhesive strips are required to have qualities such as 'low-tack' or moisture-resistance. The plaster’s adhesive properties as are important as the selection of the strip material and surface.

Tuesday, 17 September 2019

Texture Analysis of Beverages

The word “beverage” does not conjure up images of Texture Analysis, which is best suited to samples with properties ranging from viscous liquids to solids. However, with raw ingredients and packaging to consider, beverage manufacturers have just as much need for Texture Analysers as any other industry.

With a worldwide drive to reduce plastic consumption, paper straws have made an appearance in many bars and restaurants. They are an excellent alternative and a blast from the past for some consumers, coming in a wider range of patterns than we are used to seeing on plastic straws. However, a drawback of paper straws is their lack of structural integrity once they have spent some time soaking in a drink. The softened end not only has an unpleasant mouthfeel; it also reduces the straw’s effectiveness.

With a worldwide drive to reduce plastic consumption, paper straws have made an appearance in many bars and restaurants. They are an excellent alternative and a blast from the past for some consumers, coming in a wider range of patterns than we are used to seeing on plastic straws. However, a drawback of paper straws is their lack of structural integrity once they have spent some time soaking in a drink. The softened end not only has an unpleasant mouthfeel; it also reduces the straw’s effectiveness.

Tuesday, 10 September 2019

Texture Analysis of a Spa Day

A trip to a spa is a feast for the senses designed to be as indulgent and relaxing as possible. Scented candles, smooth creams and scrubs rid the guest of layers of tired skin and rejuvenate their spirits.

It is not a surprise, then, that the texture of the products involved is of high importance to manufacturers looking to supply high end spas, and Stable Micro Systems have a testing solution for almost every circumstance.

It is not a surprise, then, that the texture of the products involved is of high importance to manufacturers looking to supply high end spas, and Stable Micro Systems have a testing solution for almost every circumstance.

Tuesday, 3 September 2019

Using Texture Analysis Data to Predict the Results of a Sensory Panel

For example, sensory panels are expensive but there is an alternative that can allow companies to lean away from this particular cost.

Sensory perception can be correlated with parameters measured using a Texture Analyser to simplify product development, investigating the mechanisms by which physical food properties act to produce specific sensations during consumption. Once appropriate equipment has been purchased, the measurement of physical parameters is often seen as an efficient alternative to costly sensory panels. Consequently, many studies in vastly different areas of the food industry have been performed with the aim of establishing methods that reflect in-mouth sensory properties using physical parameters.

Tuesday, 27 August 2019

Texture Analysis update in the Petfood World

The very best in nutrition for our animal friends.

Four out of five pet owners consider their pet a member of the family and with 79% saying the quality of their pet’s food is as important as their own, it is not surprising that the premium sector accounts for 40% of the $26 billion US pet food market.

Four out of five pet owners consider their pet a member of the family and with 79% saying the quality of their pet’s food is as important as their own, it is not surprising that the premium sector accounts for 40% of the $26 billion US pet food market.

Tuesday, 20 August 2019

Six recent interesting articles about Texture Analysis

For those who are new to this field of science, the following recent articles give a good introduction in several explanatory styles and highlight the importance of food texture:

Tuesday, 13 August 2019

Is your Ice Cream Tub at the Top of the Stack?

The structure of the ice cream should be protected – any decorations or surface construction should remain in place and not be squashed by the lid. At the same time, there are requirements for packaging to be lightweight, stackable and suitable for nesting in pallets during shipping as well as minimising both empty space and material usage.

Tuesday, 6 August 2019

Altering Data Acquisition Rate and Corner Frequency to Optimise your Texture Analysis

Otherwise known as sampling frequency, the data acquisition rate of a test is defined by the number of data points collected per second (pps). In general, a higher data acquisition rate allows the collection of more detail during a test. The maximum possible data acquisition rate has increased over the years with improved technology and increased computer memory.

The recently released Connect range of Texture Analysers allows data collection up to 2000pps. This higher acquisition rate (2000pps) detects up to four times as many force changes per second as the previously available rate (500pps) and so it is very well-suited to applications involving high rate fracture, such as crispiness or high speed events such as in the measurement of adhesives or brittle samples.

Tuesday, 30 July 2019

Why change from the Standard Method approach?

|

| Tape Unwinding Rig A/TUR |

A standard test method can be considered an experiment that determines one or more characteristics of a given sample and the detail of the test method is usually as a result of creation from a number of experts in that measurement field. Within the materials testing industry, for example, there are an enormous number of standard methods (e.g. ASTM, ISO) that have been developed to measure specific sample characteristics.

Tuesday, 23 July 2019

Textural Measurement of Gelatine

Tuesday, 16 July 2019

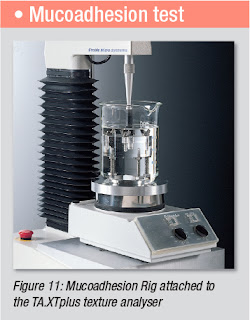

Mucosal Delivery: Measuring Product Texture

Mucoadhesion is the process by which a drug delivery device is designed to stick to a part of the gut or other mucosae (buccal cavity, nasal, rectal and vaginal), thus delivering drug to a precise site in the body for an extended period.

This gives more effective treatment of some diseases and can also protect drugs from some of the harsh conditions in the body. Mucoadhesive drug delivery systems are used to treat several conditions in the mouth and have been investigated as treatments for stomach ulcers and cancer. The majority of infections affecting man and animals take place or start in mucous membranes. The ability to retain pharmacologically-active agents for extended periods of time on any mucosal epithelium, including those of the nose, mouth, rectum or vagina confers several potential therapeutic advantages.

Thursday, 20 June 2019

Transdermal Delivery: Measuring Product Texture

TRANSDERMAL DELIVERY

TRANSDERMAL DELIVERYTransdermal drug delivery as a route for systemic drug administration is currently one of the advancing areas in drug development research.

This is particularly true for the delivery of such drugs as opiate painkillers, birth control, nitroglycerin for the prophylaxis of angina, nicotine for smoking cessation therapy, testosterone for the correction of male hypogonadism.

The skin route for systemic drug delivery is especially attractive to formulators, as this integument is the most readily accessible organ of the body. Clinicians are increasingly recognising the advantages of controlled continuous intravenous infusion of drugs, such as the avoidance of hepatic metabolism and the maintenance of a constant therapeutic level in the body, that can be obtained by the use of the skin as a portal of drug delivery, without the risks and costs of intravenous therapy.

Developing dermal, transdermal and mucoadhesive delivery systems

INTRODUCTION

INTRODUCTIONDevelopments in transdermal, dermal and mucoadhesive drug delivery methods are paving the way to the future of systemic drug administration.

As skin is both the largest and most accessible organ in a human body, pharmaceutical manufacturers are keen to take advantage of it as a drug delivery platform.

The transdermal route helps to reduce the risks and costs of intravenous therapy that can be both traumatic and intrusive.

Transdermal controlled release (CR) systems usually combine a therapeutic component with an adhesive formulation that ensures a continuous delivery of the active ingredient through unbroken skin at a constant absorption rate. Skin adhesion and drug compatibility determine the efficacy of transdermal applications.

Parenteral Texture Control: Rectal Delivery Products

RECTAL DELIVERY

RECTAL DELIVERYAlthough administration via the peroral route is the most commonly targeted goal of new drug and dosage form research and development, oral administration is not always feasible or desirable.

The potential for oral dosage form development is severely limited for active agents that are poorly absorbed in the upper gastrointestinal (GI) tract and unstable to proteolytic enzymes. Some agents cause local stomach or upper GI irritation or require doses in excess of 500mg.

Additionally, treatment of some diseases is best achieved by direct administration near the affected area, particularly with diseases involving anorectal tissues. Although oral administration can be used for drugs targeted for some of these diseased tissues, exposure of the entire body compartment to the administered drug is inefficient and can lead to undesired adverse effects.

Tuesday, 18 June 2019

Parenteral Texture Control: Vaginal Delivery Products

VAGINAL DELIVERY

The vaginal route of administration offers a promising option for local and systemic delivery of drugs.

Suppositories, creams, gels and tablets are commonly used vaginal drug delivery systems. These conventional vaginal formulations, however, are associated with limitations of poor retention, leakage, and messiness, thereby causing inconvenience to users.

To overcome these limitations, formulations that adhere to the vaginal mucosa for a sufficient period of time need to be developed. Bioadhesion and retention are desirable characteristics of a vaginal formulation to achieve desired efficacy. These properties can be built in during formulation development by the use of bioadhesive polymers and tested by similar methods to those already discussed for bioadhesion. The limitations have also necessitated the development of other novel drug delivery systems.

The vaginal route of administration offers a promising option for local and systemic delivery of drugs.

Suppositories, creams, gels and tablets are commonly used vaginal drug delivery systems. These conventional vaginal formulations, however, are associated with limitations of poor retention, leakage, and messiness, thereby causing inconvenience to users.

To overcome these limitations, formulations that adhere to the vaginal mucosa for a sufficient period of time need to be developed. Bioadhesion and retention are desirable characteristics of a vaginal formulation to achieve desired efficacy. These properties can be built in during formulation development by the use of bioadhesive polymers and tested by similar methods to those already discussed for bioadhesion. The limitations have also necessitated the development of other novel drug delivery systems.

Tuesday, 11 June 2019

Parenteral Texture Control: Ocular Delivery Products

OCULAR DELIVERY

OCULAR DELIVERYTreatment of some diseases is best achieved by direct administration near the affected area, particularly with diseases involving ophthalmic, optic, dermal, oral cavity, and anorectal tissues.

Ocular drug delivery is an interesting and challenging opportunity for pharmaceutical development. The eye is protected by a series of complex defense mechanisms, which usually result in poor bioavailability of drugs administered via the ocular route. These include tear production and the blinking reflex in addition to short residence time and reduced drug permeability.

Tuesday, 4 June 2019

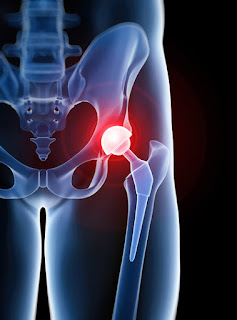

Parenteral Texture Control: Parenteral Delivery Products

Developments in injectable depots and implants are driven by a desire to decrease the necessity for frequent medication.

Incorporating polymer technology for slow, long-term release, this route is best utilised for the treatment of chronic conditions, such as heart disease and pain management. Hip or knee cap replacements are susceptible to infection following surgery.

A preventative approach could be for the doctor to leave behind an implant that could deliver an anti-infective agent and disintegrate with time. These devices give localised, high-concentration delivery, and by tuning the ratio of drug load to polymer the required release rate can be optimised, over two days or two months.

Tuesday, 28 May 2019

Parenteral Texture Control: Pulmonary Delivery Products

PULMONARY DELIVERY

Pulmonary delivery has been used for years to treat respiratory diseases by delivering drugs locally to the lung.

However, the latest advances are seeing drugs being delivered via this route for systemic circulation. The delivery of drugs to the bloodstream via the lungs is an attractive hypothesis, offering a non-invasive and rapid-onset alternative to injections.

Inhalation Drug Delivery via Metered-dose Inhalers

Aerosol route of administration targets drugs directly to the lungs and offers advantages of bypassing the first pass elimination, reducing the dosage frequency and minimising the extent of adverse drug reactions.

Tuesday, 21 May 2019

Parenteral Delivery: Under Control

INTRODUCTION

INTRODUCTIONThe latest craze to sweep the pharmaceutical industry is one of controlled-release drug delivery systems.

This controlled release can be systemic (generally via the bloodstream), as is generally the case for oral preparations, or act specifically at the site of greatest benefit (for example, in implanted devices) and these dosage forms are defined as preparations that modify the rate and/or the time and/or site of release of the active ingredient, in order to achieve specific therapeutic objectives which cannot be achieved with conventional dosage forms similarly administered.

Tuesday, 14 May 2019

How to operate a Texture Analyser using a range of devices

Whether you are new to texture analysis, are an experienced super user, or have specific requirements, you now have the flexibility to choose how you interact with a Connect Texture Analyser.

Whether you are new to texture analysis, are an experienced super user, or have specific requirements, you now have the flexibility to choose how you interact with a Connect Texture Analyser. We offer three ways to run your instrument. Each can be used independently from each other, or you can have a combination of all three. Whichever suits your requirements, the choice is yours.

How to operate your Texture Analyser

Touchscreen

The Touchscreen is supplied with all of our Connect Texture Analysers and is capable of controlling your instrument and running simple tests. It is ideal for providing a quick result with some single point analysis, such as Maximum Forces in both compression and tension tests.

Wednesday, 8 May 2019

Texture Analysis in Action: the Universal Peel Rig

The UNIVERSAL PEEL RIG (A/UPS) is a flexible solution to peel testing.

The UNIVERSAL PEEL RIG (A/UPS) is a flexible solution to peel testing.Significant improvements have been made to previous designs of peel rig for evaluating the quality and strength of container seals and adhesive bonds.

The Universal Peel Rig consists of a multi-position platform which is adjustable to allow the container to be held at 0, 45 and 90 degrees; the platform is screwed securely into position on the base of the Texture Analyser to suit the container.

Tuesday, 7 May 2019

Performance and textural properties of personal care products

PERSONAL CARE PRODUCT PACKAGING

PERSONAL CARE PRODUCT PACKAGINGNot only are the texture and physical appearance of personal care products crucial for achieving aesthetic appeal and optimal functionality, but other factors concerning their look and feel can dictate their popularity.

The packaging of a product can have a profound influence over purchasing decisions. Catchy names and bright colours are part of the attraction but packaging that performs the essential preservation function and is easy to use is also a key persuasion.

Regardless of product density, several texture analysis examinations can aid manufacturers in producing the best packaging to suit the personal care product in question. With tubs, tubes, sachets and various other vessels being available, it is essential that the correct packaging format is chosen in order for consumers to make complete and convenient use of their personal care products.

Tuesday, 30 April 2019

Performance and textural properties of personal care products

PEELABLE PERSONAL CARE PRODUCTS

PEELABLE PERSONAL CARE PRODUCTSMeasuring Peeling Characteristics

There are many personal care products which rely upon a good peeling function as their primary physical characteristic.

Medical bandages, sanitary towels, and nappies are just a few examples of products that at some point will require to be peeled from skin or another surface and therefore this adhesive strength will need to be measured in order to be monitored and/or controlled. Waxing strips are used as a method of hair removal at home and are typically treated with wax to remove hair.The benefit of waxing strips are that they do not require a heat source in order to grip the hair. Whether applying cloth strips to heated wax on unwanted hair in a salon or whether using formulated strips for home-use the success of this treatment is based on the adhesive interaction that occurs with the hair in order to remove it when the strips are peeled off.

Tuesday, 23 April 2019

Performance and textural properties of personal care products

GELS

GELSHydrogels are becoming a major influence in personal care products today.

There is a need for hydrophilic, skin adhesive, biocompatible hydrogels that can be used in a variety of applications such as shampoo, hair setting gels, face masks, skin fresheners and scented gels (air fresheners). Currently there are numerous hydrogels on the market, ranging from viscous solutions to elastic solids. The reason for this recent interest is that hydrogels can act as moisturising agents and they can deliver numerous therapeutic ingredients in a controlled manner.

Thursday, 11 April 2019

How to measure performance and textural properties of personal care products

CREAMS, EMOLLIENTS & SHAMPOOS

CREAMS, EMOLLIENTS & SHAMPOOSRheological properties of semisolids are highly important physical parameters in both technical (manufacturing, filling, storage) and aesthetic terms.

The evaluation of semisolid emulsion structure and consistency is therefore essential in order to determine, adjust, and possibly predict the corresponding product performance. The emulsifier concentration in the formulation of the cream and the manufacturing temperature are just two variables that can effect the flow and viscoelastic properties as well as the resistance to deformation.

Tuesday, 9 April 2019

How to measure performance and textural properties of personal care products

WAX/PETROLATUM

WAX/PETROLATUMWaxes are an important component of many personal care products such as skin care, baby products, suntan and sunscreen and lubricating agents.

The measurement of hardness (or firmness) of these waxes has long been an important assessment to ascertain their contribution to final product texture. The hardness of waxes (which is affected by their melting point) may have a significant effect upon other physical properties and a measurement of hardness is used to determine whether a wax is suitable for use in products to provide rigidity, good moulding properties, or is capable of producing soft emollient films with good lustre.

Tuesday, 2 April 2019

How to measure performance and textural properties of personal care products

SOAP & DEODORANT

SOAP & DEODORANTSoap must have the required degree of plasticity within an operating temperature of 30-40°C.

It is particularly important to achieve the correct plasticity at the final pressing stage, since the compressed bar must be subject to a minimum of internal pressure to avoid serious cracking when the bar is used. To achieve the required degree of plasticity, certain factors must be controlled. For the dried soap base, these are: water content after drying; glycerol and electrolyte content; and the nature and quantity of any additives used in the liquid soap pre-drying.

Tuesday, 26 March 2019

How to measure performance and textural properties of personal care products

INTRODUCTION

INTRODUCTIONBefore paint was ever splashed onto canvas or cave walls, it was daubed on faces and bodies, not only for symbolic purposes but for decoration too.

Today, a plethora of beauty products are seen lined up in the display windows and shelves of shops and stores everywhere.

The cosmetics and personal care market is extremely crowded, making it an extremely competitive arena. In this industry, the combination of good marketing and product quality must be compelling to gain shelf space, consumer attention and repeat purchase.

Tuesday, 19 March 2019

Testing texture in reformulated food

Staying firm on sugar reduction

Already in the crosshairs of health-conscious consumers, these days sugar is frequently demonised in the media.

Legislation across the globe is mandating the reduction of sugar in a variety of products, as well as demanding clearer labelling in an effort to educate and discourage consumers. Where soft drinks began, the rest of the food industry is expected to follow. As a result, manufacturers’ need to reformulate with lower sugar content is higher than ever.

However, beyond adding a sweeter taste, the reduction or removal of sugar also impacts the texture of foods which must be addressed. Jam, for example, relies on sugar for firmness. Whether being spread on toast or added to cakes, the firmness of jam is crucial to consumer enjoyment and has a direct impact on its perceived quality.

Already in the crosshairs of health-conscious consumers, these days sugar is frequently demonised in the media.

Legislation across the globe is mandating the reduction of sugar in a variety of products, as well as demanding clearer labelling in an effort to educate and discourage consumers. Where soft drinks began, the rest of the food industry is expected to follow. As a result, manufacturers’ need to reformulate with lower sugar content is higher than ever.

However, beyond adding a sweeter taste, the reduction or removal of sugar also impacts the texture of foods which must be addressed. Jam, for example, relies on sugar for firmness. Whether being spread on toast or added to cakes, the firmness of jam is crucial to consumer enjoyment and has a direct impact on its perceived quality.

Tuesday, 12 March 2019

Testing texture in reformulated food

Low-fat without low-quality

Low-fat without low-qualityWith global obesity levels at an all-time high, and an improved understanding of the impact of fat on the function of many major organs, low-fat diets are a common approach used by many consumers hoping to improve their health.

This trend has had huge implications for the dairy sector, where, to meet this demand, thousands of product lines are being reformulated, and many more are being launched from scratch. From dairy drinks and yoghurts to cheeses and dairy desserts, the low-fat trend is visible everywhere.

Tuesday, 5 March 2019

Testing texture in reformulated food

Measuring strength and stickiness in low-salt

According to the World Health Organization (WHO), adult salt intake of less than five grams per day can help to reduce blood pressure and the risk of cardiovascular disease.

In response, WHO member states have pledged to reduce the global population’s intake by a relative 30% by 2025. As such, low-salt launches, including the revolutionary change to Heinz soup recipes to provide reduced sodium options, are rife in the market. Yet, while health authorities worldwide agree too much salt can be bad for health, it does have an important role in texture – particularly in cooked meats, where it ensures firmness and “bite,” and baked goods, in which it plays a multitude of textural roles.

Tuesday, 26 February 2019

Testing Texture in reformulated food

Introduction

IntroductionConsumers are more aware of, and knowledgeable about, their health than ever before.

This increased focus has led to people following a variety of different diets, with a wide range of dietary specifications, putting pressure on manufacturers to develop a portfolio of foods and drinks to meet individual needs. In many cases, this involves reformulating an existing product to have more of a particular ingredient, such as higher protein content, or less of another, including salt, fat and sugar.

Tuesday, 19 February 2019

How to measure Engineering Terms with your Texture Analyser

Each calculation is designed to be used with a very specific test setup (for example, cuboid three point bend testing) as the specific equations required for analysis depend on the sample and test geometry. A help page is supplied within the software for each quick calculation explaining the parameters that must be entered into the software by the user (such as film thickness) and a derivation and reasoning behind every equation used.

Tuesday, 12 February 2019

Texture is the final frontier of food science

More than ever, products must feel right

Tweaking texture could give us healthy versions of our favourite junk foods – and that's just the beginning.

According to a recent Popular Science article, food’s texture, called rheology, is so intricately tied to our food preferences that it’s becoming a bona fide area of study.

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) uses computational models to study how food moves and interacts with all of the surfaces of the mouth – technology previously used to predict tsunamis – to help better understand the connection.

Tuesday, 5 February 2019

How to Measure Whole Fruit Volume

Quality

components of fruits and vegetables are classified into the external

such as size (weight, volume and dimensions), colour, shape

(diameter/depth ratio), external defects etc. and the internal such as

sugar content, acid content, firmness, maturity etc and internal

characteristics.

Quality

components of fruits and vegetables are classified into the external

such as size (weight, volume and dimensions), colour, shape

(diameter/depth ratio), external defects etc. and the internal such as

sugar content, acid content, firmness, maturity etc and internal

characteristics.Agricultural products have the characteristics of being ‘low value added’ as compared with other industrial commodities. Because of this, application of start-of-the-art technology to agricultural sectors has been relatively recently activated and various up to date techniques have now reached the point of practical implementation.

Tuesday, 29 January 2019

Fruit Texture: How to measure consistency of fruit preparations

The market for fruit preparations continues to grow, in large part due to their health and natural image.

The addition of fruit is immediately seen to add value, as well as sophistication, to products, from yoghurt to fresh cheese and ice cream. Consumers look for a high level of large fruit pieces, evenly suspended, with a natural texture.

Today fruit preparations are technologically advanced ingredients which can fit perfectly into the end user’s applications – sweet and viscous or low in fat, but very high in fruit content. The correct stabiliser system is also crucial for obtaining the desired texture from the fruit preparation. Modified starches, gums and gels are essential to control viscosity and texture and to guarantee the stability of the fruit preparation.

The addition of fruit is immediately seen to add value, as well as sophistication, to products, from yoghurt to fresh cheese and ice cream. Consumers look for a high level of large fruit pieces, evenly suspended, with a natural texture.

Today fruit preparations are technologically advanced ingredients which can fit perfectly into the end user’s applications – sweet and viscous or low in fat, but very high in fruit content. The correct stabiliser system is also crucial for obtaining the desired texture from the fruit preparation. Modified starches, gums and gels are essential to control viscosity and texture and to guarantee the stability of the fruit preparation.

Tuesday, 22 January 2019

Fruit Texture: How to measure properties of fruit leather, fruit films and fruit peel

Fruit Leather

Fruit LeatherA fruit leather is made by drying a very thin layer of fruit puree or a mixture of fruit juice concentrate and other ingredients on a flat surface in an oven, desiccators or in direct sunlight, to obtain a product with a chewy texture similar to soft leather.

Almost any type of fruit is suitable for making fruit leathers. Fruit leather is easy to eat, convenient to pack, and makes an ideal popular snack almost anywhere for a mouth-watering sugar boost. When dried, the product is usually pulled from the surface, rolled and consumed. The control of the drying temperature is very important, as very high temperatures may cause case hardening, hindering the outflow of water. Too thin a layer of purée, on the other hand, can make the product brittle and difficult to be pulled from the surface.

Tuesday, 15 January 2019

Fruit Texture: How to measure firm pastes and dried fruit flakes

Measuring Firm Paste Texture

Texture is a very important property of fruit pastes since they are often used as fillings for energy bars and other products containing fruits.Among all textural properties, hardness and stickiness are the most important, since they can dictate the possibility of application onto a product. Usually fruit pastes are applied by lightly heated rollers. If the paste is too hard or sticky it may not be properly applied.

Subscribe to:

Comments (Atom)