Quality

components of fruits and vegetables are classified into the external

such as size (weight, volume and dimensions), colour, shape

(diameter/depth ratio), external defects etc. and the internal such as

sugar content, acid content, firmness, maturity etc and internal

characteristics.

Quality

components of fruits and vegetables are classified into the external

such as size (weight, volume and dimensions), colour, shape

(diameter/depth ratio), external defects etc. and the internal such as

sugar content, acid content, firmness, maturity etc and internal

characteristics.Agricultural products have the characteristics of being ‘low value added’ as compared with other industrial commodities. Because of this, application of start-of-the-art technology to agricultural sectors has been relatively recently activated and various up to date techniques have now reached the point of practical implementation.

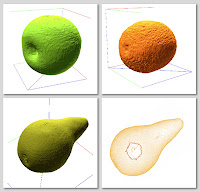

An obvious yet highly valued property of any fruit is its volume. Until recently, this external characteristic has been measured by basic means of water displacement. Though straightforward and simple, the test produces a single isolated figure. More advanced methods, involving computer-assisted recording of multiple parameters, mean it is now possible to scan a sample digitally, from which an on-screen 3D image of the fruit is generated. As such, the contours of the fruit can be used as parameters to calculate its precise dimensions.

One such example is the use of a VolScan Profiler (as shown above) – a benchtop laser-based scanner that measures the volume of products. This measurement system offers considerable advantages over displacement techniques which purely measure volume. The rapid 3-dimensional digitisation of products enables an automatic calculation of several detailed dimension related parameters the results of which may be mathematically manipulated for immediate use or future retrieval in a variety of different data formats.

How to measure Volume

The product is mounted at each end (left) and the test started. The sample is automatically weighed and a laser measures the contours of the sample at given intervals while it rotates. Once the VolScan Profiler has completed a test, data (below right) may be viewed in 2D or 3D, to allow visual comparisons with previous archived measurements.Laser-based scanners with associated intuitive software, such as the VolScan Profiler, can have vast implications on internal and external operations – from sourcing to quality control and assessment. Controlled, repeatable analysis not only provides unambiguous quality assessment standards but also offers precision in physical characterisation.

Whatever type of fruit product is being produced – thick and chunky, smooth with tiny fruit pieces – its texture must match consumer sensory preferences. The ability to produce accurate and repeatable data on different food textures is central to achieving the optimum texture quality for the end-product. The TA.XTplus Texture Analyser and its attachments is currently the most advanced of its type and facilitates such efficient and cost-effective testing, helping food processors to develop technically superior products.

For more detailed information of texture analyser settings, specific sample preparation procedures and data analysis techniques on this and any of the above mentioned tests please contact Stable Micro Systems: appsupport@stablemicrosystems.com

Watch the video below to see a summary of the types of testing possibilities that are available for the measurement of fruit and vegetable texture to provide quality control tools and ultimately, consumer satisfaction:

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

|  |  |

No comments:

Post a Comment