WAX/PETROLATUM

WAX/PETROLATUMWaxes are an important component of many personal care products such as skin care, baby products, suntan and sunscreen and lubricating agents.

The measurement of hardness (or firmness) of these waxes has long been an important assessment to ascertain their contribution to final product texture. The hardness of waxes (which is affected by their melting point) may have a significant effect upon other physical properties and a measurement of hardness is used to determine whether a wax is suitable for use in products to provide rigidity, good moulding properties, or is capable of producing soft emollient films with good lustre.

Measuring Hardness

A standard test such as ASTM D1321-95 using a needle probe (for petroleum waxes) or ASTM D937-92 using a conical probe for petrolatum provides a means of measuring the firmness or consistency. Such measurements are useful for selecting or specifying, or both, a petrolatum of a particular consistency or firmness.Standard Method ASTM D937-92 (Figure 3) specifies the use of a penetrometer to determine the extent of penetration of a standard cone. The penetrometer applies a standard cone (of 45 degrees at 25°C) to the sample (prepared under standard conditions) for 5s under a load of 150g and the penetration depth, to which the cone penetrates into the ‘wax' under defined conditions, is recorded.

In many modern industries the penetrometer has been replaced by computerised texture analysis systems which have a greater degree of accuracy and do not need to rely on the manual calculation of results or have the restriction of measurements which use the speed of gravity for the testing of samples. The standard method is therefore modified slightly to use the specified parameters and procedure (of the Standard) on the TA.XTplus Texture Analyser.

During the test the texture analyser holds a force of 150g for a duration of 5 seconds and within this time the distance penetrated will change according to the hardness of the sample. A large penetration distance would indicate a 'soft' sample whereas a small distance of penetration would indicate that the sample has a stronger resistance to penetration and is therefore ‘harder'.

Besides this measurement, which simulates a ‘penetrometer set-up', there are also alternative methods of measurement using the TA.XTplus Texture Analyser where, for instance, a force is measured to penetrate to a specific distance using a hemispherical or ball probe (Figure 4). The standard method specifies that the sample be prepared and poured into a specific container. It may, however, be preferable to perform ‘one hit' tests on samples which have already been formed into a container in which they are to be sold (as shown). In this case, the chosen container dimensions should be specified and remain constant for the purpose of comparison.

The test may be performed at a temperature of your choice (such as within the range to which the product is likely to be subjected to) but when reporting results this test temperature should always be specified for the purpose of comparison.

Measuring Stickiness

Hair waxes and pomades are the ultimate flexible styling product but are potentially heavy and greasy if not used in the correct quantity and can vary enormously in consistency, primarily in its hardness and stickiness. They primarily hold hair through seam welds – found where hairs cross each other to create a support structure and are glued together by the polymer.

This holding power is created by the waxy material’s internal stickiness or cohesiveness. The waxy materials do not “dry” because they are not water soluble. The positive benefits of not drying means that the bonds can be easily remoulded by running your hands through your hair – the negative aspect is one of potential stickiness of formulations.

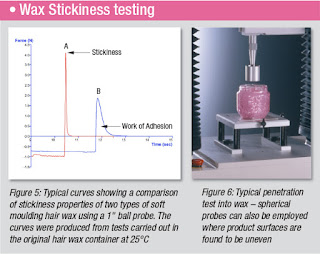

A simple penetration test using a cylinder probe or spherical probe (if the product surface is not flat) can provide a measure of product firmness. Such measurements are useful for selecting or specifying, or both, a wax of a particular consistency or firmness depending upon the required end product consistency. However, Exponent software provides the means of controlling the TA.XTplus Texture Analyser in a specialised Adhesive Test.

A cylinder probe or spherical probe applies a specified force to the surface of the sample for a specified time (to achieve a good contact between the two surfaces) and then moves away from the product at which point the force to separate the two surfaces is measured and used as a measure of product stickiness/adhesiveness/tackiness (Figure 6).

The magnitude of the absolute positive value (Figure 5) corresponds to the 'Stickiness'. The area under the profile represents the energy required to separate the wax from the probe ‘Work of Adhesion'. The larger the maximum peak force, the stickier is the sample.

Temperature Control

Severe temperature changes will affect the firmness and stickiness of the wax product, making it more or less difficult to remove the desired quantity from the container when required. Texture analysis at different temperatures can be carried out with the use of a Temperature Cabinet (Figure 7) which attaches to the Texture Analyser. Tests can then be performed within the cabinet over the range of temperatures to which the product is expected to be subjected.

Measuring Spreadability

Personal care products such as lotions, creams, gel shaving creams, etc. are often very shear sensitive and difficult to prepare consistently for testing. Penetration and compression style tests are simple methods that give results of sample hardness. However, hardness measurements, even with cone probes, are not always good discriminators of spreadability.

Spreadability, in pragmatic terms, is the ease with which a product can be applied in a thin, even layer. Firmness or hardness may be measured by the force required to obtain a given deformation or by the amount of deformation under a given force.

Although spreadability is also a deformation under an external load, it is a more dynamic property. Measurements of firmness and spreadability are usually highly correlated; however the relationship is rarely perfect, and this is partly a function of work softening. Some waxes work-soften more easily than others, which allows them to be more spreadable even when hardness values are initially equal.

The Spreadability Rig is a set of precisely matched male and female perspex 45° cones (Figure 8). The material is allowed to set up in the lower cone or is filled into the lower cone with a spatula. The material is pressed down only so much as is needed to eliminate air pockets which are visible through the perspex cones, and then the surface is levelled with a flat knife. Excessive work is not introduced into the product.

The fixture comes with five replaceable female cone sample holders which can be filled in advance of testing and then easily locked into the base holder precisely centred under the matching upper cone probe. The sample holders can be stored in refrigerated environments, or they can be used at room temperature. As long as the material has not been excessively worked, different styles of filling the material only affect the early part of the test.

The important action that the test is designed to measure, spreadability, occurs only in the later stages of the test. During these stages the product is squeezed out from between the male and female cones. The cone-shaped holder offers no locations into which the product can be packed or compressed, so the product flows outward between the male and female cone surfaces producing curves similar to those shown in Figures 9/10. The probe withdrawal, i.e. looking at the negative forces, may also offer some insights into adhesive behaviours.

The peak force (maximum force to shear) and ‘work of shear’ (area under the curve = total amount of energy required to perform the procedure) are recorded. Both of these values have been shown to rank samples in the same order of spreadability (and firmness), but for other samples one may prove to be more suitable than the other.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

Watch the video below to see a summary of the types of testing possibilities that are available for the measurement of cosmetic and skincare products.

You can also visit our website's Cosmetics and Skincare Applications page...

|

No comments:

Post a Comment