Developments in injectable depots and implants are driven by a desire to decrease the necessity for frequent medication.

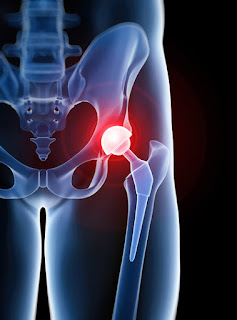

Incorporating polymer technology for slow, long-term release, this route is best utilised for the treatment of chronic conditions, such as heart disease and pain management. Hip or knee cap replacements are susceptible to infection following surgery.

A preventative approach could be for the doctor to leave behind an implant that could deliver an anti-infective agent and disintegrate with time. These devices give localised, high-concentration delivery, and by tuning the ratio of drug load to polymer the required release rate can be optimised, over two days or two months.

In cancer treatment, for example, you ideally want to be able to deliver the drug right to the tumour, or implant a device close to the tumour that will deliver the agent over time. Such a solution could be found in the use of bioresorbable polymers, which are similar in structure to disintegrating sutures used to close some wounds. This area represents the fastest growing market in the field of drug delivery.

In recent years, implants and injectable polymers have revolutionised many types of surgeries, but the ratio of inactive to active ingredients must be optimised to ensure both a therapeutic effect and ease of use. Gel substances and hydrogel polymers are increasingly prominent in mucosal and other delivery systems.

The accurate definition of gel properties is pivotal for manufacturers of products as diverse as wound dressings, jelly lubricants and contact lenses.

Measuring Gel Strength, Rupture Force & Elasticity

The measurement of gel strength is of widespread interest in the manufacture of pharmaceutical, medical and cosmetic products. Gel properties such as elasticity and rupture force of, for example, pectin, gelatine, agar etc. are important in the development of such products as coronary stents where hydrogel polymers are selected due to their soft, rubbery nature which gives them a strong, superficial resemblance to living, soft tissue.Other products for which gel-forming properties are useful are in the manufacture of wound dressings, jelly lubricants, contact lenses, suppositories, soft gel capsules and bacterial growth media. The strength of gels can also be utilised in products such as toothpaste, creams and pastilles to modify the consistency of the required end product.

It has been shown that for controlled release systems based on cellulosic ethers, for example, that the viscosity grade of the polysaccharide can be used as a strong predictor of the release characteristics of soluble drugs from the matrix. The properties of the gel can be measured by the mechanical resistance to stress of an aqueous gel of the material, of particular concentration.

Using a cylinder probe (typically 1" radiused) the probe is lowered into the gelled system at a fixed rate to a distance of, for example, 15mm, which does not lead to fracture of the gel surface. The strength of the gel is assessed as the peak force (i.e. the force to reach the chosen distance) or the force to penetrate to a smaller chosen depth.

Standard probes such as that required for

gelatine testing (according to the ISO Standard), as shown in Figure 3,

are also available for the assessment of Bloom strength or rupture

characteristics of gels (typical graph as shown in Figure 4).

Standard probes such as that required for

gelatine testing (according to the ISO Standard), as shown in Figure 3,

are also available for the assessment of Bloom strength or rupture

characteristics of gels (typical graph as shown in Figure 4). In the case of self-supporting gels, manufacturers may wish to look into the product’s elastic moduli. Elastic moduli give an indication of a substance's tendency to be deformed elastically when a force is applied to it. This can be done by lowering a cylindrical probe onto a gel sample placed on sandpaper to prevent slipping (Figure 5). This test allows manufacturers to evaluate gel strength, elasticity and gel rupture force. Elastic moduli are determined from the initial parts of the stress-strain curves.

Cements

The injectable calcium phosphate and calcium sulphate-based ceramic bone graft substitutes are one more addition to the armamentarium of minimally invasive orthopaedic surgery. These bioceramic bone graft substitutes offer several distinct advantages over autograft and other groups of bone graft substitutes because autologous bone does not need to be harvested.

Injectable cements are generally used as an adjunct to internal fixation for the treatment of fractures or as bone void fillers in surgery or dentistry.

The ‘in vivo’ use of such biomaterials requires preventive antibiotic therapy to avoid the development of postoperative infections. This is achieved either by daily systemic administration (oral or injection) or by ‘in situ’ application. Impregnating these bone cements with controlled release antimicrobial substances is a cost-effective and clinically established method of preventing deep infection in patients.

Measuring Cement Setting Time

The

cements harden endothermically which limits tissue damage while

developing a compressive strength intermediate between cortical and

cancellous bone. The setting time of the cement is defined as the time

required for a paste to reach a fixed hardness. The resistance to

penetration of a 2mm cylinder probe at 2mm/s to 5mm penetration distance

is measured (Figure 8). A curve showing resistance exerted by the cement on the

probe versus displacement of the probe into the paste is obtained.

The

cements harden endothermically which limits tissue damage while

developing a compressive strength intermediate between cortical and

cancellous bone. The setting time of the cement is defined as the time

required for a paste to reach a fixed hardness. The resistance to

penetration of a 2mm cylinder probe at 2mm/s to 5mm penetration distance

is measured (Figure 8). A curve showing resistance exerted by the cement on the

probe versus displacement of the probe into the paste is obtained. These measurements allow determination of the “maximum of resistance versus time”. According to convention, setting corresponds to a degree of resistance to cement penetration of 600g/mm2.

Moulded cement samples are then tested for compressive strength applying load axially to the samples with a speed of 0.1mm/min. Compressive strength (C) is then determined using the following formula: C = F/S where F is the maximum load applied and S the cross-sectional area of the cylinder.

Measuring Injectability/ Syringeability

When introducing antibiotic into cement formulations, the maximum amount of antibiotic needs to be established that will allow the preservation of the mechanical properties and the injectability of the cement. The potential efficacy of an injectable cement's handling properties and scaffold for bone repair performance can be evaluated using a Texture Analyser.

The injectability is defined as the ability of cement to move through the syringe-catheter device. The force applied to move a 8cm column of cement through a 3mm diameter polyethylene catheter is typically measured using a Universal Syringe Test Rig (Figure 6). The time of injectability is the time after which the cement can no longer by injected by an operator: this corresponds to pressure lower than 1.5 bars.

Mucoadhesive polymers, as components of drug delivery systems, enable formulations to adhere to mucosal surfaces and thus may facilitate controlled drug delivery to defined sites. Mucoadhesive drug delivery systems for periodontal disease would offer several notable advantages over currently available systems, including ease of application into and good retention within the periodontal pocket. The requirement of such systems would be a high viscosity, syringeable polymeric system.

However, in formulating systems to meet a certain set of criteria, other requirements, such as good retention within the periodontal pocket, may be compromised.

An assessment of both the mucoadhesive strength and syringeability is then required to assess the potential effects of formulations and their subsequent mechanical consequences to reach an optimal performance.

The syringeability of each formulation is determined using a Texture Analyser. Formulations are transferred into identical plastic syringes to a constant height. The content of each syringe is fully expressed using the Texture Analyser in compression mode and the resistance to expression is determined from the area under the resultant force-time plot (Figure 7). Increased work of syringeability is denoted by increased areas under the curves.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

|

No comments:

Post a Comment