PERSONAL CARE PRODUCT PACKAGING

PERSONAL CARE PRODUCT PACKAGINGNot only are the texture and physical appearance of personal care products crucial for achieving aesthetic appeal and optimal functionality, but other factors concerning their look and feel can dictate their popularity.

The packaging of a product can have a profound influence over purchasing decisions. Catchy names and bright colours are part of the attraction but packaging that performs the essential preservation function and is easy to use is also a key persuasion.

Regardless of product density, several texture analysis examinations can aid manufacturers in producing the best packaging to suit the personal care product in question. With tubs, tubes, sachets and various other vessels being available, it is essential that the correct packaging format is chosen in order for consumers to make complete and convenient use of their personal care products.

Semisolids in Sachets and Tubes

Many body and face creams/masks can be found in sachet portions for quick and easy use or the provision of smaller quantities for the purpose of travelling or to provide as samples. The removal of the contents relies upon the consumer squeezing the packaging. The consistency of the contents of a sachet is fundamental to its ease of removal from the packaging when required. Assuming the orifice size remains constant, the force to squeeze the packaging depends largely on the consistency of the cream.

For products in tubes, the ability to squeeze the product out effectively is essential and is fundamental to its ease of removal from the packaging when required. If the substance is too dense, consumers will experience difficulty extracting it; if it is too fluid, the product could leak. In toothpaste manufacture, three characteristics of importance in consumer acceptance are: absence of lumps or graininess; absence of air bubbles; and the proper consistency. All of these are greatly influenced by the manufacturing procedure and its control, and the selection of raw ingredients.

In terms of consistency, the binders play a very important role. The purpose of the binder is to hold all of the ingredients of a paste together and to provide the proper consistency and texture. It is desirable that a toothpaste be easily squeezed out of the tube and break off cleanly when the desired amount has been extruded, but should not be so soft as to sink quickly into the brush.

Assessing Sachet/Tube Content Removal

A Sachet/Tube Extrusion Rig

(Figure 20) quantifies the force required to extrude the

contents of tube and sachet style packaging and allow manufacturers of

personal care products to quantify the ease of removal and application

of products such as ointments, creams and gels. The rig allows the

positioning of the end of a sachet or tube vertically between two

rollers, clamping the closed end with a grip at the top. The grip then

pulls the sachet/tube upwards through the rollers, forcing the contents

out. The higher the force recorded during this test, the more difficulty

a consumer would experience in squeezing out the required amount (Figure 21).

A Sachet/Tube Extrusion Rig

(Figure 20) quantifies the force required to extrude the

contents of tube and sachet style packaging and allow manufacturers of

personal care products to quantify the ease of removal and application

of products such as ointments, creams and gels. The rig allows the

positioning of the end of a sachet or tube vertically between two

rollers, clamping the closed end with a grip at the top. The grip then

pulls the sachet/tube upwards through the rollers, forcing the contents

out. The higher the force recorded during this test, the more difficulty

a consumer would experience in squeezing out the required amount (Figure 21).This test was designed to provide product developers with a means to analyse changes in a product’s consistency throughout its shelf-life and adapt formulations accordingly, whilst also enabling manufacturers to assess the suitability of packaging material and its construction. Such a test at this stage of production could spell the difference between a successful and appealing product and one which will destroy the possibility of upgrading from sample sachet to long-term purchase of the high value larger volume personal care product. For manufacturers, failure at the last hurdle would bring disappointment and huge material losses.

Measuring Packaging Peel Strength

A large number of personal care products, including lotions and gels, as well as various types of liquid and powder make-up, are sealed with a peel-back lid.The performance of these seals is not only critical to the quality and safety of products, but is also a vital factor in user-friendliness. The adhesive bonds must be strong enough to withstand handling, shipping and storage without rupture or breakage, while being easy to peel back when necessary. Analysis of their efficiency will allow manufacturers to create optimum packaging, ensuring product safety and customer satisfaction.

A Peel Rig is used widely to evaluate the quality and strength of seals and adhesive bonds on personal care packaging. The Universal Peel Rig incorporates a multi-position platform, allowing containers to be held flat, or at 45° and 90° angles. As such, manufacturers can more precisely simulate the action of consumers, or handlers, to accurately assess both ease of use and stability of packaging seals.

The Universal Peel Rig is placed on the base of Stable Micro Systems’ TA.XTplus texture analyser and secured into position to suit the sample container. An adjustable rubber strap encircles the container to hold it in place, while a peel clip connected to the arm of the TA.XTplus holds the lid (Figure 23). As the arm moves up, the force required to peel open the lid is recorded. Exponent software measures force against distance/time (Figure 24), ensuring the efficacy of the peel back lid, and measuring the effort required to open it. Manufacturers can use the data to establish an optimum force, high enough to resist breakage but not so high that the consumer will experience difficulty in opening the package.

In addition, a simple peel test of a section of packaging seal (using Tensile Grips, as shown in Figure 22) can indicate the potential problems arising from packaging seals. Variation of weld control (the time that heat is applied), or cooling control settings (the time allowed for the weld to set prior to the opening of the sealing equipment), can be investigated using this test, to attempt to optimise seal strength of each packaging material in use.

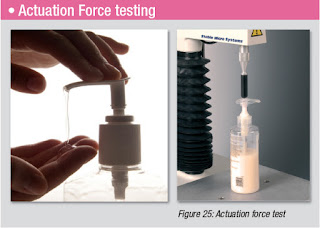

Measuring Actuation Force

Actuation

Force testing (Figure 25) allows measurement of the force

required to, for example, release hair fixatives or air freshening

sprays from aerosols, or liquid soap, shampoo or cream from dispensers.

Manually-actuated spray pump dispensers or finger pumps rely on the

consumer to generate a hydraulic pressure in the pumping engine in order

to dispense the fluid. Dispenser designs may change or vary or the

ever-increasing market for child-friendly products may require

adaptations.

Actuation

Force testing (Figure 25) allows measurement of the force

required to, for example, release hair fixatives or air freshening

sprays from aerosols, or liquid soap, shampoo or cream from dispensers.

Manually-actuated spray pump dispensers or finger pumps rely on the

consumer to generate a hydraulic pressure in the pumping engine in order

to dispense the fluid. Dispenser designs may change or vary or the

ever-increasing market for child-friendly products may require

adaptations.When operating a pump-type liquid soap dispenser, for example, a child may have difficulty applying sufficient force in the appropriate direction to operate the pump, which may cause the dispenser to move, tip, or otherwise fail to discharge the product toward the intended target. An actuation force test, where a hemispherical or cylinder probe pushes down onto the product specific actuation spot and measures the force to deliver a desired quantity of the container contents, provides an imitative test to assess such issues.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

Watch the video below to see a summary of the types of testing possibilities that are available for the measurement of cosmetic and skincare products.

You can also visit our website's Cosmetics and Skincare Applications page...

|  |  |

No comments:

Post a Comment