SOAP & DEODORANT

SOAP & DEODORANTSoap must have the required degree of plasticity within an operating temperature of 30-40°C.

It is particularly important to achieve the correct plasticity at the final pressing stage, since the compressed bar must be subject to a minimum of internal pressure to avoid serious cracking when the bar is used. To achieve the required degree of plasticity, certain factors must be controlled. For the dried soap base, these are: water content after drying; glycerol and electrolyte content; and the nature and quantity of any additives used in the liquid soap pre-drying.

The fatty acid composition of the original soap must also be considered. Electrolytes have an adverse effect on plasticity when present in excess amounts. A salt excess will cause a soap to lose much of its plasticity, making it friable. A deficiency in electrolytes, conversely, produces soap which is too plastic. Additives used at the amalgamation stage of the finishing operation may also cause variations in plasticity. This is also true of medicaments and deodorant chemicals. These materials tend to make the soap soft and almost sticky which can be troublesome at the pressing stage.

Measuring Hardness

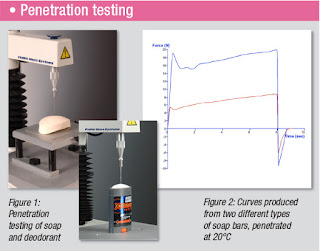

The ASTM D937-92 method, described for the hardness measurement of wax, is also suitable to assess the hardness of soap and similar products such as deodorants. The sample can either be prepared and poured into a specific container, or it may be preferable to perform ‘one hit' tests on samples which have already been formed into the container in which they are to be sold. The sample may then be conditioned at a chosen test temperature before performing the penetration test. Once

the trigger force is attained, the force increases as the probe

proceeds to penetrate into the sample. The area under the curve is the

work required to penetrate the sample to the specified distance. The

higher this value, the ‘harder' the sample is, as more work is required

to penetrate to the specified distance. Alternatively, the maximum

positive force, is the force required to penetrate the sample to the

specified distance. The higher this value, the harder is the sample (Figure 2).

Once

the trigger force is attained, the force increases as the probe

proceeds to penetrate into the sample. The area under the curve is the

work required to penetrate the sample to the specified distance. The

higher this value, the ‘harder' the sample is, as more work is required

to penetrate to the specified distance. Alternatively, the maximum

positive force, is the force required to penetrate the sample to the

specified distance. The higher this value, the harder is the sample (Figure 2). Solid deodorant must be easy to apply, be neither too soft or hard and should not possess a gritty or grainy texture. Besides determining soap or deodorant hardness, this test may also indicate the presence of unwanted trapped air bubbles, or a “grainy" texture (which would be displayed as fluctuations in force as the probe comes into contact with hard particles or air pockets).

To quantify this the calculation, ‘linear distance' may also be added into the analysis macro. This function calculates the length of an imaginary line joining all points in the selected region. A jagged curve would consequently produce a much larger linear distance value when compared to a smooth (non-grainy texture) curve.

In research and product development, such a test may also monitor hardness over temperatures to which the deodorant may be subjected during transportation and storage.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

Watch the video below to see a summary of the types of testing possibilities that are available for the measurement of cosmetic and skincare products.

You can also visit our website's Cosmetics and Skincare Applications page...

|

No comments:

Post a Comment