A Texture Analyser is a critical tool in various industries, particularly in food, pharmaceuticals, and materials science, for measuring the physical properties of products. Key aspects of its functionality include measurement accuracy, precision, and resolution. Understanding these concepts is essential for interpreting test results correctly and ensuring reliable data.

Measurement accuracy

Accuracy refers to how close a measured value is to the true value.

Regular calibration against known standards should retain precision and improve accuracy.

Conditions like temperature and humidity can affect accuracy and must be controlled.

Measurement precision

Precision involves the consistency of repeated measurements. High precision means that repeated measurements under unchanged conditions yield similar results. Factors affecting precision include:

- Instrument stability: A stable setup reduces variability.

- Repeatability: The ability of the instrument to produce the same results under the same conditions.

- Reproducibility: Consistency of results when tests are performed by different operators or with different equipment.

Measurement resolution

Resolution is different from accuracy and precision and is defined as the smallest change in measurement that an instrument can detect. Higher resolution allows for more detailed and subtle measurements. In most cases the resolution of an instrument is better than the stated accuracy. For a Texture Analyser:

- Step size: The incremental steps the drive mechanism can make, often controlled by a stepping motor.

- Load cell range: The range and sensitivity of the load cell influence the resolution of force measurements.

- Data acquisition rate: Higher rates can capture more detailed changes over time.

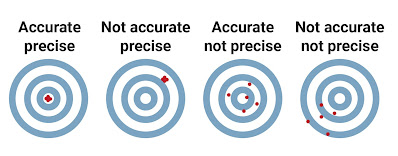

Accuracy vs. precision

Accuracy: Indicates how close a measurement is to the true value.

- In the context of a Texture Analyser, it means the measured value is close to the actual property being measured.

- High accuracy means the instrument gives a measurement that is correct on average.

Precision: Indicates how close multiple measurements are to each other.

- For a Texture Analyser, it means that repeated measurements under the same conditions yield very similar results.

- High precision means the instrument gives consistent measurements.

- Data points are clustered together and close to the true value.

- Example: Consistently hitting the centre of the target.

- Data points are clustered together but far from the true value.

- Data points are close to the true value (centre of the target) but spread out.

- Data points are spread out and far from the true value.

- Instrument calibration: Regular calibration ensures that the Texture Analyser provides accurate results.

- Environmental control: Maintaining consistent environmental conditions prevents external factors from affecting measurements.

- Sample preparation: Consistent sample preparation techniques ensure that variations are due to the material's properties, not inconsistencies in sample handling.

- Operator training: Proper training for operators minimises human error and enhances the reproducibility of results.

Why not request a Features and Safety poster for placement near your instrument to inform users:

Or if you have lost it, request a 167 page (pdf) in-depth manual to be sent to you.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplusC Texture Analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

|  |  |

No comments:

Post a Comment