Palm oil is an example of an ingredient that is frequently being replaced in food this decade. It is the oil extracted from the fleshy interior layer of the fruit of oil palms. According to “Trends in Global Palm Oil Sustainability Research.” in the Journal of Cleaner Production, it is the most produced vegetable oil in the world. In food manufacture, it is used as a flavour and moisture additive, an emulsifier and a lubricant.

While palm oil's properties make it a staple in everything from baked goods to spreads, concerns over child labour, deforestation (and the associated decline in animal populations) and climate change have driven many manufacturers to reduce its inclusion in their products, as well as looking to reduce the high saturated fat content it gives to food.

Challenges in palm oil replacement

Food developers are increasingly tasked with creating palm-free alternatives that meet consumer expectations for taste, texture, and performance. This is also an area of interest in scientific research, with efforts focused on the change in physical properties and taste before and after palm oil’s replacement.

Replacing palm oil in food products is no small feat. Palm oil contributes a unique texture that affects mouthfeel, stability, and shelf life. Finding alternatives that can perform similarly without altering the consumer's sensory experience is crucial. Common substitutes include coconut oil, butter, and other vegetable oils, each with distinct characteristics.

Texture Analysis is central to the research and development of products subject to palm oil removal.

The critical role of Texture Analysers

Texture Analysers have become indispensable in this reformulation process. These sophisticated instruments measure physical properties like hardness, brittleness, adhesiveness, and consistency — all vital to mimicking the texture that palm oil imparts in food products.

For example, in the development of a palm-free cookie, the Texture Analyser can determine how modifications to fat content affect crunchiness and crumbliness. Similarly, for spreads, the Texture Analyser helps assess spreadability, ensuring that the product spreads evenly without separation, a quality traditionally ensured by palm oil.

Typical consistency measurement example:

Iterative testing and product optimisation

Using a Texture Analyser allows for iterative testing, which is essential for perfecting palm-free formulations. Through repeated testing, developers can fine-tune recipes to achieve the desired texture, thus ensuring that the new product remains as close as possible to its palm-oil-containing predecessor in terms of consumer experience.

Developing products incorporating palm oil substitutes involves finding sustainable alternatives to traditional ingredients or processing methods. Texture measurement plays a vital role in this process by ensuring that these alternatives can mimic or deliver the desired texture attributes. Accurate texture measurement enables producers to fine-tune formulations, processing techniques, and ingredient combinations to achieve the desired texture profile.

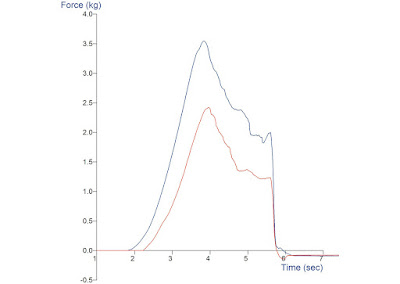

So, you’ve formulated your new product containing a palm oil substitute and you compare it with your existing product formulation on the Texture Analyser and this is the result…

Perfect reformulation provides the ‘same-as’ texture profile

|

Perfect reformulation provides the ‘same-as’ texture profile |

Bingo, you’ve done it! Your new product formulation that has been fully considered in its new ingredients and necessary processing changes provides almost the same texture profile as your existing product. Ultimately, the success of new products relies on consumer satisfaction and acceptance. Texture measurement plays a crucial role in meeting consumer expectations and preferences. Consumers have ingrained sensory expectations when it comes to the texture of specific foods. By accurately measuring and replicating these textures, manufacturers can create new products that deliver both sustainability and an enjoyable eating experience and with that comes continued product loyalty.

However, what if your two products produced considerably different texture profiles?

When the formulation or processing conditions are not yet optimised compared to the original

|

When the formulation or processing conditions are not yet optimised compared to the original |

Formulators would see that the recipe for the blue line product requires much more force to perform the same test than the red line product and therefore could be perceived as a much firmer product which could compromise customer satisfaction of the expected texture. Whilst it is possible that you’re looking to develop a product with a different texture to the original and make a marketing splash about it (having confirmed its success with a taste panel), if you’re not, then it’s back to the drawing board for further formulation or processing manipulation.

Ensuring consumer acceptance

Texture is a significant factor in consumer acceptance. A Texture Analyser provides quantifiable, objective data that can be used to align the product's characteristics with consumer expectations. This data is invaluable not only for product development but also for marketing teams to communicate the benefits of new formulations effectively.

Case studies and real-world applications

Many leading food companies are already utilising Texture Analysers to pioneer new palm-free products. For instance, Mccains are 100% palm oil free and used a Texture Analyser to develop a new line of palm-free potato fries that maintain the same crunch and satisfaction as their original formula.

Another example is Arla producing a popular vegan spread (Yeo Valley brand) that reformulated its product to be palm-free while ensuring that the spread retains its creamy texture and stability over time.

Conclusion

As the food industry continues to evolve towards more sustainable practices, the Texture Analyser proves to be an essential tool in the development of palm-free foods. By enabling precise control over the textural properties of food, it ensures that sustainability does not come at the cost of quality or consumer satisfaction. Brands that invest in such technologies are not only contributing to a more sustainable future but are also positioning themselves favourably in a market that increasingly values ethical and environmental responsibility.

A range of Texture Analysers are available varying in maximum force capacity and height options suited to the requirements of the application.

A vast range of probes and fixtures can be attached to the instruments depending upon the product/material to be tested. Whether it’s an Ottawa cell used to compare cereal crispness, a bending test used to assess biscuit fracturability or a back extrusion employed to assess the potential change of the adjusted formulation in yoghurt consistency.

Learn more about a wide range of textural properties that can be measured.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplusC texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

|  |  |

No comments:

Post a Comment