Wedge

penetration, a type of crack opening test that is particularly

suitable to testing fruit and vegetables, cheese, stiff gels and cooked

meats, involves a wedge driven into a block of material.

Wedge

penetration, a type of crack opening test that is particularly

suitable to testing fruit and vegetables, cheese, stiff gels and cooked

meats, involves a wedge driven into a block of material. The dimensions of the test specimen affect the results and so it is important to use reproducible rectangular blocks. This test is similar to a tensile test but instead of the two halves of the specimen being pulled, they are pushed out by the penetrating wedge. The two halves bend outward storing strain energy.

At the point of fracture this energy is fed to the tip of the wedge where stress concentration is highest and a free running crack starts and propagates ahead of the wedge.

In most materials this produces a stable and desirable mode of fracture. The cutting angle of the wedge is also important. With a very narrow wedge insufficient strain energy is stored to start a free-running crack. With a very wide wedge there may be a considerable degree of shear and compression involved giving unrealistic results. In most crispy foods a 30 degree wedge is sufficient. The more easily deformable the material, the wider the wedge should be.

1: Wedge Penetration

Test setup

Typical force/deformation plots and measurable fracture properties:

Interpretation of results:

Wedge tests are very similar to knife cutting tests except that as the wedge cuts in strain energy is stored in the specimen that is then available for a free-running crack to propagate ahead of the blade. Here the important events to measure are the point of wedge entry into the specimen, the force and distance at which a free-running crack is initiated and the fracture toughness (calculated from energy).

Penetration using a narrow cylindrical probe

Test setup:

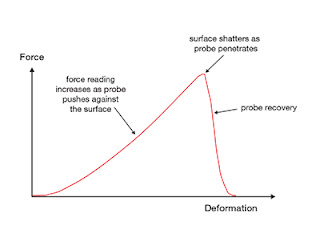

Typical force/deformation plots and measurable fracture properties:

|

| e.g. Peppers. Probe penetration tests on other vegetable products with tough skins and fleshy internal tissue will produce similar plots. |

|

| e.g. Boiled sweets or hard glassy and brittle materials. |

Interpretation of results:

In structurally complex products the probe penetration tests give somewhat similar force/deformation profiles to compression tests and hence the same interpretation applies. This test is a good way of assessing the contribution of re-enforcing components on the overall toughness of the structure, i.e. if the probe passes through the skin of a fruit the force peaks and then falls. Skin increases the toughness of the specimen. This peak is a reliable measure of the strength of the skin. In homogeneous materials, on the other hand, there is a single peak where cracking starts i.e. fracture force and distance. The harder the material the higher the peak.

Knife Cutting

Test setup

Typical force/deformation plots and measurable fracture properties:

|

e.g.

A knife cutting through layers of wafers in the biscuit gives the

following plot. This is typical of the fluctuations in force observed

when cutting through laminated specimens.

|

|

e.g. Hot-dogs and sausages. Meat and fish show a similar profile.

|

Interpretation of results:

The position of the peaks is important. These indicate that the blade is cutting through tougher or stronger layers that lie in between weaker ones. The first peak indicates the entry of the blade into the specimen. If the material caves in only slightly the force of penetration is low and the drop after blade entry is low. But in food materials there is a large cave in before blade entry giving a high peak force and then usually a large drop in force.

We can design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed, our expertise in its graphical interpretation is unparalleled. Not only can we develop the most suitable and accurate method for the testing of your sample, but we can also prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment