TENSILE GRIPS RANGE: A/TG, A/MTG and A/ATG

TENSILE GRIPS RANGE: A/TG, A/MTG and A/ATGThe gripping action of the A/TG tensile grips is provided by a screw initiated vice clamp operating on knurled jaw faces of 35mm x 35mm.

They are general purpose knurled jaw face grips suitable for holding samples which have a uniform rectangular shape and a maximum thickness of 25mm.

The A/MTG Mini Tensile Grips have smaller jaw faces of 25mm x 10mm, with a maximum opening of 8mm. Used for assessment of tensile characteristics of samples such as packaging materials, plastic and aluminium film; and also (in a cycling motion) the flexibility of e.g. chewing gum sticks and confectionery leathers.

The

A/ATG Articulated Tensile Grips are lightweight grips which have been

designed for the gripping of thin materials whilst providing a good

degree of rotational flexibility during the tensile test. This allows

for product distortion which may be necessary for unevenly adhered

products like packaging and makes loading of difficult samples easier.

The

A/ATG Articulated Tensile Grips are lightweight grips which have been

designed for the gripping of thin materials whilst providing a good

degree of rotational flexibility during the tensile test. This allows

for product distortion which may be necessary for unevenly adhered

products like packaging and makes loading of difficult samples easier.Packaging must be tough, tear-resistant and therefore provide sterility during transport and handling until the moment its contents are removed for use. It must be easy for the consumer to access without causing splitting of the packet or spilling of its contents when opening. A tensile test can assess both seal strength and integrity or provide a measure of the tensile strength of a material.

Some other Tensile Grip options are:

TENSILE GRIPS (A/HDT & A/HDG) for use with the TA.HDplus Texture Analyser:

A/HDT vice action tensile grips have a maximum holding capacity of 500kg (5kN). The jaw faces are 50mm wide and 30mm high and have a knurled finish as standard. Jaw faces with different finishes can be supplied to special order. The grips will accommodate samples up to 12mm maximum width.

A/HDG vice action tensile grips have a maximum holding capacity of 100kg (1kN). The jaw faces are 30mm wide and 30mm high, however, the design of the grips enables jaw faces up to 100mm wide and 30mm high to be accommodated.

Applications include geo-textiles, polymers and heavy-duty packaging and can be used to determine the tensile characteristics of any uniform material that can be accommodated within the grip profile.

SELF TIGHTENING ROLLER GRIPS (A/TGT)

Spring loaded cross-hatched rollers provide the self-tightening mechanism by which samples up to 45mm wide and 10mm thick are gripped.

These grips are ideal for measuring the tensile strength and tear characteristics of a wide range of materials which have a smooth surface finish or whose physical characteristics alter when a tensile force is applied. Typical examples include snack product packets and seal strength tests.

PNEUMATIC GRIPS (A/TGP & A/TGPHD)

PNEUMATIC GRIPS (A/TGP & A/TGPHD)Pneumatic grips are often a preferred means of holding a sample for tensile testing because the gripping pressure can be controlled precisely and because deformation of the specimen does not produce any change in the gripping pressure.

|

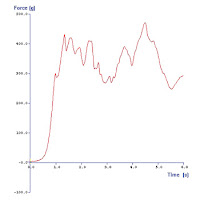

| Typical texture analysis graph - test of packaging seal strength using tensile grips |

A selection of the many Published Papers using these fixtures/principle follows:

ABU-GHOUSH, M., HERALD, T. J., DOWELL, F., XIE, F., ARAMOUNI, F. M. & MADL, R. (2008). Effect of preservatives addition on the shelf-life extensions and quality of flat bread as determined by near-infrared spectroscopy and texture analysis. International Journal of Food Science & Technology, 43, 357-364.

ABU-GHOUSH, M., HERALD, T. J., DOWELL, F., XIE, F., ARAMOUNI, F. M. & WALKER, C. (2008). Effect of antimicrobial agents and dough conditioners on the shelf-life extension and quality of flat bread, as determined by near-infrared spectroscopy. International Journal of Food Science & Technology, 43, 365-372.

AHN, Y., JANG, Y., SELVAPALAM, N., YUN, G., KIM, K. (2013). Supramolecular Velcro for Reversible Underwater Adhesion. Angewandte Chemie International Edition, 52(11), 3140-3144.

ALVES, V. D., MALI, S., BELEIA, A., GROSSMANN, M. V. E. (2007). Effect of glycerol and amylose enrichment on cassava starch film properties. Journal of Food Engineering, 78, 941-946.

ANDREUCCETTI, C., CARVALHO, R.A., GALICIA-GARCIA, T., MARTINEZ-BUSTYS, F., DIAS, T.P., GROSSO, C.R.F. (2013). Effect of the Addition of Soy Lecithin and Yucca schidigera Extract on the Properties of Gelatin and Glycerol Based Biodegradable Films. Polímeros Ciência e Tecnologia, 23(3), p.339-345.

ANTUNEZ, P., OMARY, M., ROSENTRATER, K., PASCALL, M. & WINSTONE, L. (2012). Effect of an oxygen scavenger on the stability of preservative-free flour tortillas. Journal of Food Sciences, 71 (1), S1-S9.

ARCAN, I., YEMENICIOGLU, A., (2012). Development of flexible zein–wax composite and zein–fatty acid blend films for controlled release of lysozyme. Food Research International, 51(1), 201-216.

BIKA, D., TARDOS, G. I., PANMAI, S., FARBER, L. & MICHAELS, J. (2005). Strength and morphology of solid bridges in dry granules of pharmaceutical powders. Powder Technology, 150, 104-116.

CHAMBI, H. & GROSSO, C. (2006). Edible films produced with gelatin and casein cross-linked with transglutaminase. Food Research International, 39, 458-466.

CHARLES, A. L., HUANG, T. C., LAI, P. Y., CHEN, C. C., LEE, P. P. & CHANG, Y. H. (2007). Study of wheat flour-cassava starch composite mix and the function of cassava mucilage in Chinese noodles. Food Hydrocolloids, 21, 368-378.

CHO, S. Y. & RHEE, C. (2004). Mechanical properties and water vapour permeability of edible films made from fractionated soy proteins with ultrafiltration. Lebensm.-Wiss. U. Technol., 37, 833-839.

CORRALES, M., HAN, J. H. & TAUSCHER, B. (2009). Antimicrobial properties of grape seed extracts and their effectiveness after incorporation into pea starch films. International Journal of Food Science & Technology, 44, 425-433.

CUEVAS-RODRIGUEZ, E. O., REYES-MORENO, C., ECKHOFF, S. R. & MILAN-CARRILLO, J. (2009). Nixtamalized instant flour from corn (Zea mays L.) meal: optimisation of nixtamalization conditions. Cereal Chemistry, 86 (1), 7-11.

GUJRAL, H. S., HAROS, M. & ROSELL, C. M. (2004). Improving the texture and delaying staling in rice flour chapati with hydrocolloids and alpha-amylase. Journal of Food Engineering, 65, 89-94.

HAN, J. H., SEO, G. H., PARK, I. M., KIM, G. N. & LEE, D. S. (2006). Physical and mechanical properties of pea starch edible films containing beeswax emulsions. Journal of Food Science, 71 (6), 290-296.

JO, C., KANG, H., LEE, N. Y., KWON, J. H. & BYUN, M. W. (2005). Pectin- and gelatin-based film: effect of gamma irradiation on the mechanical properties and biodegradation. Radiation Physics and Chemistry, 72, 745-750.

LOSANOFF, J. E., COLLIER, A. D., WAGNER-MANN, C. C., RICHMAN, B. W., HUFF, H., DIAZ-ARIAS, A. & JONES, J. W. (2004). Biomedical comparison of median sternotomy closures. The Society of Thoracic Surgeons, 203-209.

MALI, S., GROSSMANN, M. V. E., GARCIA, M. A., MARTINO, M. N. & ZARITSKY, N. E. (2006). Effects of controlled storage on thermal, mechanical and barrier properties of plasticized films from different starch sources. Journal of Food Engineering, 75 (4), 453-460.

OSES, J., NIZA, S., ZIANI, K. & MATE, J. I. (2009). Potato starch edible films to control oxidative rancidity of polyunsaturated lipids: effects of film composition, thickness and water activity. International Journal of Food Science and Technology, 44, 1360-1366.

PARK, S. I. & ZHAO, Y. (2006). Development and characterization of edible films from cranberry pomace extracts. Journal of Food Science, 71 (2), 95-101.

PROKOPOVICH, P., PERNI, S. (2013). Contact interations of aorta against PVC catheters. Tribology International, 66, 157-164.

RIVERO, S., GARCIA, M. A. & PINOTTI, A. (2010). Crosslinking capacity of tannic acid in plasticized chitosan films. Carbohydrate Polymers, 82 (2), 270-276.

ROMERO-BASTIDA, C. A., BELLO-PEREZ, L. A., GARCIA, M. A., MARTINO, M. N., SOLORZA-FERIA, J. & ZARITZKY, N. E. (2005). Physicochemical and microstructural characterization of films prepared by thermal and cold gelatinization from non-conventional sources of starches. Carbohydrate Polymers, 60 (2), 235-244.

RYOKAWA, H., MIYAZAKI, Y., FUJISHIMA, A., MIYAZAKI, T. & MAKI, K. (2006). The mechanical properties of dental thermoplastic materials in a simulated intraoral environment. Orthodontic Waves, 65, 64-72.

SABLANI, S. S., DASSE, F., BASTARRACHEA, L., DHAWAN, S., HENDRIX, K. M. & MIN, S. C. (2009). Apple peel-based edible film development using a high-pressure homogenisation. Journal of Food Science, 74 (7), 372-381.

SUN, Q., LI, X., WANG, P., DU, Y., HAN, D., WANG, F., LIU, X., LI, P. & FU, H. (2011). Characterization and evaluation of the Ag+ loaded soy protein isolate-based bactericidal film-forming dispersion and films. Journal of Food Science, 76 (6), E438-E443.

TAPIA-BLACIDO, D., SOBRAL, P. J. & MENEGALLI, F. C. (2005). Development and characterization of biofilms based on Amaranth flour (Amaranthus caudatus). Journal of Food Engineering, 67 (1), 215-223.

TAYLOR, J., TAYLOR, J. R. N., DUTTON, M. F. & DE KOCK, S. (2005). Identification of kafirin film casting solvents. Food Chemistry, 90, 401-408.

ZHANG, Y. & HAN, J. H. (2006). Mechanical and thermal characteristics of pea starch films plasticized with monosaccharides and polyols. Journal of Food Science, 71 (2), 109-118.

ZSIVANOVITS, G., MACDOUGALL, A. J., SMITH, A. C. & RING, S. G. (2004). Material properties of concentrated pectin networks. Carbohydrate Research, 339, 1317-1322.

We can design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed, our expertise in its graphical interpretation is unparalleled. Not only can we develop the most suitable and accurate method for the testing of your sample, but we can also prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

|

No comments:

Post a Comment