The more that you know about various features of the Texture Analyser the better it will perform for you. The following takes you through the choices you will need to go through to determine what is the best test for your product and application.

This information is also contained within the Education Zone of Exponent Connect software:

Choosing the most suitable test method and test advice

Which test, what settings?

Your first priority will be to find a suitable method for your particular sample. If your company already has a Texture Analyser we recommend that you contact the Texture Analyser operator to check whether there are any Company Standard procedures already developed for the product that you need to test.

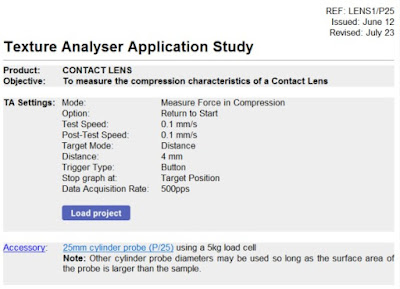

If you are looking for guidance on setting up the testing of your sample for the first time by clicking on Help – Education Zone you will see that you have a wealth of background information at your disposal (as shown below). Select the Application area into which your sample fits then you will see a set of Application Studies/Test methods that have been provided as a ‘starting point’.

Within an Application Study the ‘Load Project’ button will transfer all of the settings and analysis for your chosen test into Exponent Connect ready for you to use.

You may also wish to search for methods that use a particular probe that you may have by clicking on Probe or attachment or by the property that you wish to measure, in which case click on Textural or Physical Property.

Standard method

You may have been asked to follow a specific Standard method to test your samples, e.g. ISO Gelatine Bloom Strength, AACC Bread Freshness, AACC Pasta Firmness, ASTM Petroleum Wax Firmness, ASTM Adhesive Peel Strength.

Imitative test

If you’re not bound by any existing constraints and are looking for the most simple testing solution, sometimes the easiest approach is to set up a test that closely imitates the way the product is evaluated in real life e.g. Biting, pushing a finger into, bending, stretching? This is called an ‘Imitative Test’ (typical examples are shown below). This type of test can sometimes make data interpretation easier for you to understand.

Choosing the best test type

When deciding which test to use, ask yourself the following questions:

What test type should I choose based on my sample form?

A wide range of test principles are possible: compression, puncture, extrusion, bending, tension, shearing. Every one of these principles has been successful with some products but no principle has been successful with all products. It is important to identify as early as possible the correct test principle that should be used for each particular application. Considerable time can be wasted if an incorrect test principle is used.

First of all, consider the nature/form of the product. Is it self-supporting, semi-solid, homogeneous, multi-particulate? The kind of material (crisp, aerated, homogeneous, plastic, brittle, heterogeneous) affects the type of test principle that should be used. For example; the extrusion test is unsuited for baked goods because they do not flow under force. Equally you cannot bend mayonnaise or stretch whipped cream. If the material is not self-supporting then you obviously cannot 'cut' it in a shearing test. You can immediately eliminate some of the testing options just by considering the form that the product takes.

Which is the most suitable probe/attachment?

Generally, the test that you choose to use will fall into one of the testing categories shown above. Once your test principle is chosen you will probably have a number of attachment options within that principle to consider. For example, if you wish to perform a shearing test you will need to consider whether you require a single blade or multiple blade, which would be necessary if your product is not homogeneous so as to provide an average measurement over multiple regions of your product. You should also consider blade width, depth and thickness which will depend upon the width, height and consistency of your product.

Should my test be destructive or not?

Destructive tests ruin the structure of the sample rendering it unsuitable for repeating the test or for using the product for other purposes. Non-destructive tests leave the food in a condition close to its original state so the test can be repeated on the same item. Both types of tests are used in the food industry. Because mastication is a highly destructive process it seems logical that destructive tests should be the predominant type of tests to be used on foods.

Which method makes most sense?

After going through the above steps, the field should have narrowed to about 2 or 3 promising test types. The unsuitable test principles are to be given no further consideration. In selecting the most promising two or three tests principles it often helps to observe what kind of test principle people use in their sensory evaluation of textural quality. For example, if people judge textural quality by gently prodding with their finger (as in measuring the firmness of jam) the penetration test principle is an obvious candidate for further work; if people use snapping tests, then the bending-snapping test principle should be given consideration for further study.

In spite of the possibility of performing fundamental measurements, empirical and imitative tests are used widely for-texture measurement. Interpretation of results are usually easier and they often provide a relatively cheap and convenient form of test for quality-control purposes (Brennan, 1994).

Points to note on method choice

Testing adhesive products

The Confectionery Holder provides one means of sample securing but limits the test to penetration through a 10mm hole. A Universal Sample Clamp provides a number of options for holding a sample/sample container down in order to puncture/slice/extrude into, then out of it without the sample lifting.

Alternative simple approaches are also recommended e.g. gluing the sample to a disposable surface which can be held down or setting the product (e.g. Gel) to a self-adhesive backed velcro.

Occasionally the adhesion of a material to the sample needs to be measured. The Flexible Substrate Clamp provides a means of supporting the material (e.g. sweet wrapper) whilst the Slotted Adhesive Indexing plate holds down the sample.

|

| Universal Sample Clamp options for holding down a sample |

Measuring tensile properties

In tensile experiments the sample length should be at least twice the width.

When measuring tensile properties, the sample needs to fail in the exposed region of the test piece rather than where it is being clamped.

Protection of sample ends may be necessary by e.g. surrounding in other material onto which the grips clamp or freezing sample ends in liquid nitrogen.

Testing products with a shell, crust or skin

The collection of detail of a thin, brittle, laminated or multi-phased structure is best performed with a small diameter probe or thin, sharp fixture such as a craft knife.

Testing brittle products

When testing a brittle/laminated product e.g. puff pastry, a thin, sharp contact between the probe and product is necessary to avoid a compressive action and capture detail of the variable structure.

Free online test advice

If you are still having difficult choosing a suitable test method for your product then we can, of course, give you advice either by clicking on ‘

Request Help’ (in the Education Zone), clicking on ‘

Test Advice Service’ as you enter your Exponent Connect software or by going directly to the Support section of our website:

www.stablemicrosystems.com/forms/test-advice-service

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplusC Texture Analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

No comments:

Post a Comment