Penetration is the method used to measure consistency which is the resistance a sample exhibits to deformation by an applied force.

A Penetrometer is a device that provides a rapid empirical method for measuring the denseness, compaction, consistency or penetrability of a wide variety of solid, semisolid, food and non-food products. These typically include soil, agricultural produce, or semisolid petroleum products in the pharmaceutical (such as creams and ointments), civil engineering, agriculture, geology and scientific exploration industries.

It is a simple device that was invented in 1846 and typically measures the resistance of a substance to penetration to a given depth by a weight-driven cone or needle of a specific shape by gravity at a specific temperature. This penetration is indicated in penetration units of 0.1mm or directly in millimetres which allows a rating of the plasticity or consistency of the sample. Over time, many standard methods have developed that use this principle but vary in the penetrometer cone/needle geometry, time and load applied.

The Plus range of Texture Analysers can accommodate a Penetrometer unit to provide this measurement and extend the range of applications for the instrument.

How the Penetrometer works

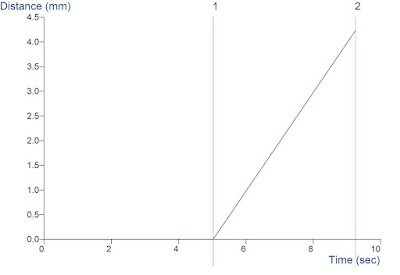

Typically, a standard cone or needle is automatically released from the penetrometer rig and allowed to free-fall into a contained sample for 5 seconds (or a different specified cone release interval) at a constant temperature after which time the cone is automatically retained. The depth of penetration of the cone or needle into the sample is measured and recorded in mm, PU (Penetrometer) units along with the additional measurement of apparent yield stress (σapp). The deeper the cone/needle sinks into the material, the softer the material is.

|

| Graph showing the cone release interval 5 seconds |

|

| Typical spreadsheet in Exponent Connect software |

|

| Penetrometer probe |

The hollow Penetrometer Probe and shaft for the European Pharmacopoeia 2.9.9 method is 150g (+/- 0.05g) and made from brass with a steel tip. This cone geometry and total weight is also in accordance with cone methods applicable to greases and to petrolatum which are described in ASTM Test Methods D 217 and Test Method D 937, respectively.

This rig and cone also complies with the following standard methods:

- IP 50

- IP 179

- BS 2000-50

- BS 2000-179

- ISO 2137

- DIN 51804

Measuring consistency – a comparison to consider

Penetrometry is a simple method that has existed long before the evolution of computer/electronic assisted possibilities of measuring consistency. It is a device that many standards can call upon and in many industries (such as petrolatum or bitumen) those standards have become a fixed framework for measurement with a reluctance to adapt to new digitised solutions.

This is a well-known case that we have encountered many times over the last few decades and one that we respect. However, for those industries or newer companies that are not bound by standard method for their sample there are published papers such as for the testing of butter that compare the TA.XTplusC Texture Analyser (with a range of different fixture options) with a penetrometer to show a high correlation. Findings concluded that: The cone penetration test is undoubtedly the fastest and the simplest method of analysing the textural properties of butter. Cone penetrometers are relatively cheap, and they generate repeatable results if sample temperature is carefully controlled. The results of this study indicate that the values of the textural properties of butter measured with different analysis systems can be compared. Penetration tests conducted with the use of a cone probe or a cylinder probe are rapid and easy to perform, and they can effectively replace shear tests.

Find out more by visiting our Penetrometer product page

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplusC texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

|  |  |

No comments:

Post a Comment