What is an actuation test?

An actuation test measures the process that occurs when a mechanical device operates. For example, the release of a hairspray aerosol, a liquid soap hand pump, an inhaler barrel or a keyboard or camera button. It is a non-destructive test, simply causing a device to function in the way in which it was designed and used to measure every aspect of interest of this function.

Why are actuation tests important?

Many characteristics of actuation can be measured but in the case of an aerosol, hand pump or inhaler, the main parameter required is the force used to expel its contents and the travel (distance) that occurs during actuation.

|

| Measuring the force to actuate and sample delivery weight |

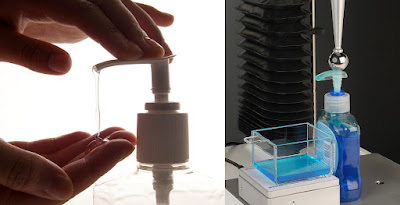

Pump dispensers come in many shapes and sizes, designed to dispense a specific quantity of product with each pump. They are operated by a finger press, with the user pushing down to build up pressure on a piston within. As with any packaging, changes in design occur to keep up with visual trends or to suit certain user groups such as children or the elderly. In these groups, users can find a sufficient force application and correct pump direction difficult to achieve without tipping or moving the dispenser. The same principles apply to aerosol dispensers. An actuation test using a Texture Analyser is useful for such products to assess these issues. A hemispherical probe is most commonly-used as representative of a finger press, providing an imitative test.

For packaging that dispenses a sample upon actuation, the use of a Dynamic Integrated Balance provides an additional high speed weighing parameter. During the test, the deposited sample is simultaneously weighed while force, distance and time data are collected. Post-test, users can view the product quantity and deposition rate on a second axis alongside force data.

|

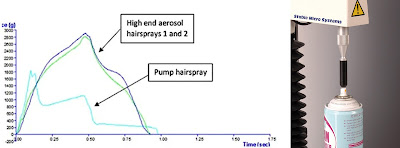

| Typical graph showing actuation force measurement comparison of dispensers |

Metered Dose Inhalers

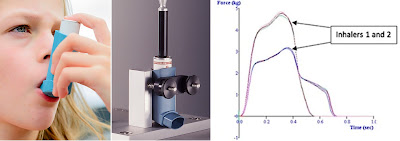

Actuation mechanisms are often used for drug delivery. For example, a metered dose inhaler is commonly-used to treat lung conditions such as asthma, delivering a precise drug dose into the lung with each pump. Patients rely on this precision and often need the inhaler to provide them with their medication at a time when their physical strength is low.

The actuation properties of an inhaler can be measured using a Texture Analyser, which imitates the downward movement of the finger, measuring the force needed to actuate the spray and administer the dose. This is a simple test and uses a specially designed Metered Dose Inhaler Test Rig.

The metering valve, which is assessed using this test, is a critical component of a finished metered-dose inhaler. Metering valve systems can be affected by alterations to design, and product performance is dependent on the interaction between the elastomeric components and the drug formulation. Re-designs of the valve are often necessary after changes to the formulation, such as the use of a new propellant system, to ensure the drug can still be delivered with minimum difficulty.

|

| Typical measurement of a metered dose inhaler |

Computer Keyboard

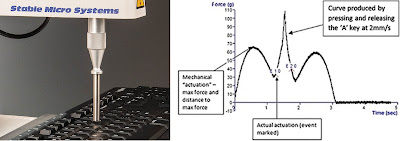

During an objective test on a keyboard, the switches are primarily under investigation, and these are actuated by pressing keys. During a key actuation test, the keyboard is placed on the base of the Texture Analyser and a domical probe used to press and retract a key in a controlled manner. Each key may be tested in this way.

The key’s force-distance profile gives information on the force required to overcome the ‘tactile bump’, as well as the distance at which this force peak occurs. Electronic actuation can happen at any point on the key’s travel. To record this point, Exponent software is set up to record an ‘event’ when the key is actuated, marking a point on the curve. This can be used to measure the key’s pre-travel before actuation and to compare the tactile and electronic actuation points.

|

| Typical measurement of computer keyboard key |

In the case of all electronics buttons including keyboards and push buttons, there are several other calculations from the actuation graph that may be of interest. For example, the shape of the force profile, the reset point (when the key is no longer activated upon unloading), the time before actuation and the hysteresis (the distance between actuation and reset). Several other aspects of the key performance could also be investigated using this type of test set up, for example the effect of post-test speed on the forces involved, the force profile itself and the unloading behaviour. These can all be added to the analysis macro as necessary.

The addition of an Acoustic Envelope Detector adds useful information regarding the user’s experience of pressing the button, as the sounds involved are distinctive and an important contribution to the feel and perceived quality of the product.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplusC texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

|  |  |

No comments:

Post a Comment