Egg Testing

Providing high quality eggs and egg products is crucial to the sustainable economic viability of the egg industry. Surveys conducted in the EU indicated that shell strength, albumen quality (consistency and height) and intensity of yolk pigment are the main measures of quality important to consumers. Guaranteeing quality is essential to meeting consumer expectations.

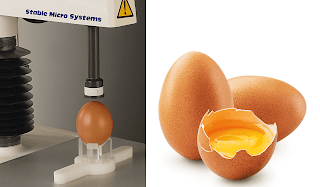

The Egg Quality System, also known as the Egg Testing Kit, provides the tools that enable the producer and packer of poultry eggs to accurately and consistently measure the quality of their produce in a rapid and simple testing process. They can regularly monitor a range of parameters to ensure that their eggs meet the required quality standards and that these are maintained throughout the laying period. Exponent software for the Texture Analyser provides the operator with parameter options from which to choose the tests to be performed on each egg.

|

| Typical Egg Shell Strength Test using the Egg Quality System |

Published research examples that use this test:

- Impact of egg handling and conditions during extended storage on egg quality – The international trade of shell eggs has become more important in recent years in order to feed a growing worldwide population, meet food manufacturing demands, and address supply issues during disease outbreaks or product recalls. The primary barriers for the export and import of shell eggs are: whether to wash eggs and egg storage temperature. The current study was undertaken to compare egg quality factors as influenced by egg washing and storage temperature. Scientists from the US National Poultry Research Center used their TA.XTplus Texture Analyser to measure shell breaking strength and egg yolk strength.

- Survey of egg quality in commercially available table eggs – Increased demand in consumer choice has resulted in a wide variety of egg selection available in the retail market. Specialty and designer chicken eggs represent a portion of the table egg market that is increasing in size. Egg quality is known to be of great importance in all eggs as it relates to food safety, consumer preferences, and product value. In this study, egg quality characteristics were analysed. Researchers from California State University Fresno investigated egg quality in commercially available table eggs. Eggs were evaluated for shell and content weight, dimensional measurements, and they used their TA.XTplus Texture Analyser to measure breakage force. Calculations were completed to determine %yolk and albumen, yolk index, and Haugh unit.

Using the Volscan Profiler to assess egg dimensions

The Volscan Profiler is useful for the measurement of dimensional aspects of eggs, a process that can be difficult to perform manually. Egg volume and surface area are important parameters to consider both in the poultry industry and biological studies, assisting with the prediction of chick weight, egg hatchability, shell quality characteristics and egg interior parameters.1

|

| Schematic drawing of narrow and round egg geometry |

Additionally, some egg shapes have a greater tendency to crack than others. Cracked eggs lead to waste, which in turn leads to a cost for the manufacturer, so reduction in cracking is crucial. Eggs with a regular shape are able to withstand more pressure during handling, fit properly into packaging and require a greater force to break compared to round or narrow eggs.2

Methods for manual measurement of egg dimensions currently in use include water displacement for volume, fitting formulae for surface area and Vernier callipers for shape parameters. These methods are generally unreliable and operator-dependent.

|

| Typical test and result using the Volscan Profiler |

Laser profiling for egg dimensional measurement is an emerging technology using established equipment such as the Volscan Profiler. Eggs are well-suited to measurement with a laser as they have a smooth, solid surface with an overall convex curve.

Published research examples that use this test:

- Hen genetic strain and extended cold storage influence on physical egg quality from cage-free aviary housing system – In the United States, there is an increase in need for cage-free eggs in retail and food manufacturing sectors. Understanding the impact of cage-free systems and the corresponding management on egg quality is pertinent as the U.S. industry adapts existing housing and builds new cagefree housing structures. Scientists from USDA Agricultural Research Service used their Volscan Profiler to determine volume of shell, total length, maximum width, and percent length at maximum width to more accurately indicate egg shape than shape index. The outcomes from this study can be utilized by the U.S. egg industry in planning management strategies and market placement of cage-free eggs.

- Evaluation of Management of Laying Hens and Housing Systems to Control Salmonella and Other Pathogenic Infections, Egg Contamination, and Product Quality – Researchers from Purdue University considered that determining the size, shape, and density of the avian egg has always presented a problem. The measurements require an individual’s visual perception to determine the data points. The smooth surface and ovoid shape of the shell makes using micrometers to determine shape index difficult. Placement of micrometers varies by each individual. Historically, determining the specific density of an egg has required the egg be placed in saline solutions of known concentrations to assess at which concentration the egg ‘floats’. Again, this measurement required the visual perception of when an egg is ‘floating’. Objective determination of egg shape, volume, and density can be found in one minute per egg using the Volscan Profiler. Measurements include egg length, maximum width, shape index and length at maximum width, producing a 3D image of the egg. Repeated measurement of the same egg produces less than 1% variability in measured outcomes. The egg shape and volume information from this device can be utilised by poultry breeders, producers, and processors, as well as, housing and processing equipment and egg carton manufacturers.

- Evaluation of current and emerging techniques for measuring eggshell integrity of the domestic fowl – Eggshell function is two-fold; eggshells function to protect the developing embryo, as well as act as a barrier against bacterial penetration, optimising food safety of the egg for human consumption. Two trials were conducted by scientists from the University of Kentucky in order to determine differences in eggshell microstructure of eggs produced from hens at peak lay and at the end of lay. Eggs were scanned using the Volscan Profiler, creating a 3D image of each egg and egg length and width, which were used to calculate shape index, were also measured.

The modern requirement for food that is simultaneously appealing, convenient and easy-to-prepare places a large amount of pressure on manufacturers. This optimisation of taste and texture requires trial and error, using techniques that efficiently measure and quantify the effects of these procedures on meat such as poultry. Using a variety of specially designed attachments, food manufacturers and processors can ensure that the textural quality of their poultry products is optimum, thereby ensuring consumer satisfaction. With the use of Texture Analysis and Laser Profiling, poultry processors can easily determine factors relating to the quality of meat and eggs.

1 Narushin, V. G. “Egg geometry calculation using the measurements of length and breadth.” Poultry science 84.3 (2005): 482-484.

2 Nolan, Lauren Wood. “Evaluation of Current and Emerging Techniques for Measuring Eggshell Integrity of the Domestic Fowl.” (2019).

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

No comments:

Post a Comment