In modern chocolate manufacturing, automated equipment has replaced the manual processes that traditionally relied largely on the experience and skill of the chocolatier. For quality control purposes and customer satisfaction, it is increasingly important to apply the correct processing conditions and controlling parameters, such as time, temperature, moisture content and the relative humidity of the surrounding air. The careful choice of these parameters will not only aid the manufacturing process, they will ensure a top quality product straight from the factory, and after a period of storage.

Chocolate is a dispersion of sugar and cocoa particles in a continuous phase of cocoa butter. In milk chocolate, non-fat milk components are also present in the dispersed phase and butter fat is present in the continuous fat phase. When the liquid product is not properly tempered and cooled, higher melting point glycerides solidify within an oily mass. The resulting product has poor texture and a tendency to develop fat bloom on cool storage. The texture of chocolate is generally quite stable on storage unless the product is subjected to extreme temperature fluctuations, which cause melting and solidification. This leads to textural deterioration as attributed above to uncontrolled solidification of cocoa butter during processing. This can, to some extent, be prevented by addition of lecithin. Sometimes chocolate develops a sugar bloom.

Many different test methods are suitable for the measurement of chocolate texture, ranging from penetration and cutting to compression and bending.

|

| Example of a three point bend test |

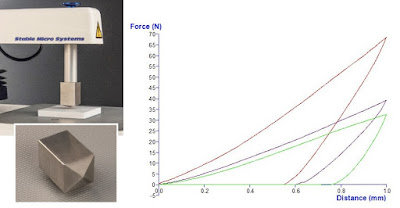

The breaking strength of rigid samples such as chocolate can be determined by performing a three-point bend test. In this test, a sample is supported across a span of known distance, a force is applied to the centre of the sample (which is also central to the supports) and the breaking force is determined. Such a test may, for example, be used to assess the effect of different ingredients used, or to examine typical finished product problems such as moisture uptake.

The breaking strength (force per unit width) or breaking stress (force per unit area) of the chocolate sample is taken as the maximum strength or stress value of the curve. Other textural characteristics that may be of interest are the distance to break and the gradient of the slope during application of force, giving a measurement of the sample’s stiffness. The distance to break gives an indication of the brittleness of the chocolate as this shows how far a sample can be deformed before fracture.

Vickers testing has been a very widely-used technique for many materials for decades due to simple data analysis and test preparation. Many applications demand a tip made from a very hard material such as diamond or sapphire, as the indenter must be significantly harder than the material under investigation. However, stainless steel is suitable for testing many softer materials such as tablets, soap, fruit and vegetables, cheese, chocolate and some polymers.

Traditionally, Vickers hardness is calculated by inputting the indentation diagonals into a standard formula. However, instrumented indentation on a Texture Analyser allows automatic hardness analysis without the use of a microscope. It also enables other parameters such as stress relaxation and elastic-plastic energy ratios to be calculated. This stainless steel Vickers indenter is designed for fast and repeatable hardness testing of soft materials, such as those often used in the food, pharmaceutical and personal care industries.

Depending on the sample type, it may be tested directly on the instrument base, or it may be more convenient to use a container or the Heavy Duty Platform. The use of a platform is recommended for chocolate testing to help insulate the sample from the warmth of the instrument base.

In an example study, six samples were tested: white and dark chocolate tested immediately after being frozen to -18°C, after being refrigerated to 4°C and at room temperature (21°C). The samples were placed on a plastic cutting platform for indentation testing.

|

| Vickers probe and curves produced from testing white chocolate |

The above curves were produced from testing white chocolate at 21°C, 4°C and -18°C. It can be seen as the sample temperature is decreased, the maximum force increases, indicating a higher sample hardness.

Samples made up of multi-layers, such as a chocolate bar with layers of cream, chocolate, biscuit or wafer, can be penetrated with a thin probe or cut with a craft knife. It is important to carry out these measurements with a slow test speed so the properties of each layer can be determined separately. The following image shows a knife test cutting through layers of wafer in a chocolate bar. This is typical of the fluctuations in force observed when cutting through laminated specimens.

An important property of chocolate during the manufacturing process is its adhesion when demoulding. Experimental determination of chocolate adhesion to a mould was carried out by researchers at the University of Leeds (Keijbets, Chen and Vieira, 2010), using a fixture developed specifically for this work.

The surface adhesion force, or stickiness, was measured by pulling a flat polycarbonate probe off a solidified chocolate sample, as shown in the schematic diagram below. This imitated the forces involved in the demoulding process of commercial chocolate bars. Processing parameters such as temperature, contact time and environmental humidity have a significant impact on chocolate crystallisation and solidification processes and on the adhesion of chocolate to a mould surface. A Peltier Controlled Cabinet is invaluable in this type of chocolate experimentation, as it provides a controlled temperature range between 0 and 50°C.

There are numerous projects integrated into Exponent software that can be applied to chocolate testing. Additionally, when these are combined with user-generated projects (as seen in the last example), the enormous capability and flexibility of Stable Micro Systems’ Texture Analysers can be seen.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

No comments:

Post a Comment