Almost every manufacturing industry has to deal with powders and granules at some stage during production. Depending on the nature of your powders, you will have different testing priorities.

There are three main test methods programmed into Exponent software for Powder Flow Analysis: caking, cohesion and powder flow speed dependency (PFSD), as well as variations such as cohesion measurement at four speeds.

Each test begins by default with two conditioning cycles to remove any user loading variation and to normalise the powder column after filling. Bulk density measurement has also been programmed into each of these sequences when the user chooses to use their split vessel, which sweeps the powder off the bulk down to a set line after conditioning. Additionally, the addition of a Powder Caking and Consolidation Rig allows the assessment of the sample’s caking behaviour after consolidation.

Caking

Caking behaviour in powders is typically undesirable and can be very difficult to measure. Understanding a powder's propensity to cake in advance is enormously useful for decisions regarding powder formulation, production before scale up, powder blending, handling, packaging, storage and transportation.

Caking is the tendency of a powder to form large agglomerates during storage and transportation. The tendency of a powder to cake is closely related to its cohesiveness and generally a powder that is cohesive will also form a definite cake during the caking test. The strength of the cake will depend on a number of factors such as packing efficiency, particle to particle interactions and moisture content i.e. humidity. Understanding the caking properties of a powder are important as most powders will be stored in hoppers or silos, or transported at some point in the production process. A powder that cakes easily and forms a strong cake may not discharge easily from a silo when required.

This test gently compacts the powder column to a user programmed force, then slices back to the top of the column with minimum disturbance, before recompacting. This is repeated for the programmed number of cycles and the rotor blade then slices the compacted cake. The cake height is measured at the beginning of each cycle.

|

| Cake height ratio trend for a range of samples |

Scientists from Universiti Putra Malaysia have been researching banana powder production via foam mat drying using caking strength. Read more

Scientists from Erciyes University (Turkey) have been researching powder caking and cohesion behaviours of coffee powders as affected by roasting and particle sizes, using principal component analyses for flow and bioactive properties. Read more

Cohesion

Cohesiveness is the tendency for particles of powder to cling together and agglomerate (form larger clusters of particles). The Powder Flow Analyser measures this cohesion characteristic by moving the blade in such a way as to lift the powder. A more cohesive powder will cling to itself and to the blade therefore reducing the force exerted on the base of the vessel. This is shown in the plotted data by a large negative force.

This quick analysis allows repeatable quantification of the cohesiveness of a bulk solid. Test results can be used to compare the sample being tested with previously analysed product, to assess if it is more cohesive or more free flowing. A Cohesion Index is determined that characterises the flow behaviour of the product from extremely cohesive to free flowing.

|

| Cohesion Index table |

Researchers from Erciyes University have also been investigating the influence of sucrose reduction and starch type on bulk and powder properties of ready-to-use powdered dessert. Find out more

Scientists from the University of Zagreb have been researching the optimisation of the foam mat drying process for the production of cocoa powder enriched with peppermint extract. Read more

PFSD

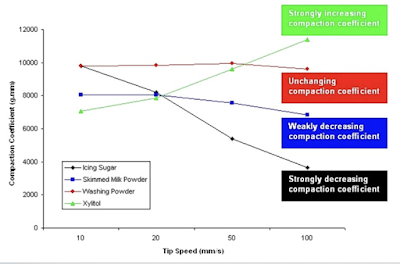

Powder flow properties may change with increasing or decreasing flow speeds. For example, a powder may become more resistant to flow as it is forced to flow faster or it may become more free-flowing as the flow speed increases. This issue can lead to under filling, for example, as a result of process changes to meet increase output demand. The Powder Flow Analyser measures this characteristic by assessing the work needed to move the blade though the powder at increasing speeds.

An evaluation of the flow stability of the powder is made by comparing the work needed to move the blade though the powder (compaction coefficient) at the start of the test compared to the work required to move the powder at the same speed at the end of the test. Powders that flow freely will transfer very little resistance through the powder column in either a downward or an upward direction. Conversely, poorly flowing powders exhibit substantial amounts of force in either direction.

|

| Compaction coefficient trends with increasing tip speed for a range of samples. |

The Powder Caking and Consolidation Rig

Scientists from the Medical University of Gdansk have been investigating the use of novel tools for the assessment of powders and granules flow properties and for the analysis of the minitablets compression process. The purpose of this study was to apply rheological measurements to assess the flow properties of powders and granules and to compare the results with the standard pharmacopeial tests. Read more

Many powder difficulties run into by manufacturers are due to the effects of storage, with the powder settling, caking and consolidating over time and under its own weight. The tendency of a powder to cake can give important data about the properties of the powder after storage and transportation. The formation of strong cakes may lead to issues with discharge of powders from storage hoppers or silos and may also impact on customer perception of products – as it could appear that the product is less voluminous than stated.

The effects of time and pressure on a powder’s flow properties can be assessed using the Powder Caking and Consolidation Rig. This rig is designed for location on a Powder Flow Analyser, allowing the assessment of the sample’s caking behaviour after consolidation.

Using this rig, the sample is prepared by filling a static consolidation tube to a chosen volume or weight. A compaction weight is introduced into the tube and allowed to rest on the powder column under controlled environmental conditions for a given period of time after which the sample is tested using the PFA blade. The area under the curve in the mid-section of the graph is taken as the work to break the cake. The greater this value, the stronger the cake.

Researchers from Lovely Professional University (India) have been investigating moisture sorption isotherms and quality characteristics of onion powder during storage as affected by sprouting using this test. Read more

Stable Micro Systems offer a large range of testing possibilities for your powders on top of Powder Flow Analysis. These include Unconfined Yield Stress, Powder Vertical Shear, an Indexable Powder Compaction Rig, High Tolerance Powder Compaction for tabletting research and Granule Compaction.

To read about ‘Measuring Powder and Granule Properties to anticipate problems’ using the Powder Flow Analyser and a wide range of other powder measuring tools for the Texture Analyser, request our article.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

No comments:

Post a Comment