Processed root and tuber products

Processed root and tuber productsThermal treatment is one of the most important processes in the manufacture of storable and ready-to-serve food products of agricultural origin.

During thermal treatment, many desirable and undesirable reactions take place; components such as vitamins and colour components, for example, and also physical properties, such as texture, may be changed.

Cooking just to the point of softness produces vegetables with optimal texture which is where texture analysis plays a major role in determining processing times.

A suitable test to monitor effects of processing time of e.g. potato salad preparation, or effects of changing quantities of additional ingredients for e.g. "mash", is to use an Ottawa Cell. Processed root and tuber products like these typically have a predominantly homogeneous (uniform) structure. A typical curve is shown and highlights a plateau region obtained during the extrusion test. The measurement of the mean force obtained over this plateau region and an area calculation are most often recorded as indicators of texture differences between batches, changing formulation or modification in processing parameters.

|

An Ottawa Cell attached to a Texture Analyser with a typical curve obtained from the testing of "mashed" potato |

Hard-to-cook defect in legumes

The inability of beans to soften during a reasonable cooking time can develop in beans when they are stored at high temperature and high relative humidity. This defect results in poor quality products and increased fuel costs, lowering the commercial value of the beans. Much research has been and continues to be done on the mechanism of bean hardening. However, there is no general agreement on the exact mechanism. Cooking quality is an important quality characteristic for pulses (e.g. peas, lentils, chickpeas, and beans) because they are commonly consumed after cooking in various types of foods. Cooking is required to ensure acceptable sensory quality.

Texture is one of the most important quality factors influencing consumer acceptance of cooked pulses, and so the evaluation of the texture and firmness of cooked pulses is critical to the determination of cooking quality. An AACCI method was developed in 2013 for the determination of the firmness of cooked pulses. A collaborative trial based on ten laboratories analysing 26 blind duplicates of thirteen different samples were tasked to evaluate the repeatability and reproducibility of the method.

After cooking (according to the standard preparation procedure) the firmness of pulse samples is determined using a TA.XTplus Texture Analyser loading approximately 7.5g of cooked sample into a Mini Kramer Shear Cell. The sample is compressed and extruded at 1.5mm/s. The firmness of the cooked sample is defined as the maximum force required to shear the cooked sample and expressed as the maximum shear force per gram of cooked sample (N/g of cooked sample). According to the AACCI method 56-35.01, firmness values should be an average of six determinations.

It is taken for granted that the texture of canned vegetables resembles that of overcooked vegetables. Just like with fruit, the softening effect is due to pectin degradation and calcium displacement. It can be reduced by addition of calcium to the canning liquid. Once degraded, the texture of canned vegetables is fairly stable on storage. Vegetables stored for a significant period of time prior to processing are more prone to softening on canning. Testing using a Multiple Puncture Probe can be performed within the can to assess the overall texture of the sample by creating an averaging effect, thereby presenting a quick and easy test with minimal sample preparation.

Frozen vegetables have a better appearance than canned and their texture is expected to resemble that of fresh, firm-cooked vegetables. Additionally, the texture of vegetables is less susceptible to damage on freezing than that of fruit texture.

Cell breakage causes a lot of this damage and is related to the rate of freezing. As with other high moisture products, slow freezing causes the formation of large ice crystals leading to destruction of the cell and leaching out of cell contents. Small ice crystals do not rupture the cell membrane, so the texture of fast-frozen products is less degraded.

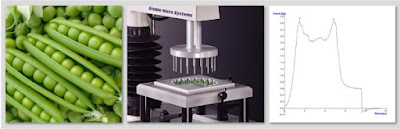

The texture of fresh and defrosted peas can be measured in comparison using the Multiple Pea Test Rig. This rig measures the force to simultaneously penetrate up to 18 samples. Puncture strength and penetration force are measured and the penetration distance set so that the probes penetrate completely through the sample. Two peaks are seen on the force-time graph – one each as the probes break through the top and bottom surface skins, either side of a plateau as the probes push through the mealy flesh.

Pickles

Pickled and / or fermented vegetables such as cucumbers and olives soften during storage, and this is considered undesirable by the consumer. A test ideally suited to measuring pitted olive texture is a Kramer shear cell test. The cell is used for analysing multi-particle products such as cereals and pickles in sauce together with fruit and vegetables.

This test applies a combination of compression, shearing and extrusion and allows an averaging effect by measuring multiple samples in bulk. This is also a suitable means of testing irregular shaped floret type vegetables such as broccoli or cauliflower. However, the floret head will often soften prior to the stalk that has more fibrous consistency and a penetration test using a cylinder probe within the stalk is recommended as a batch quality predictor.

|

| Typical test using a Kramer Shear Cell |

For jarred pickles that have smaller pieces of vegetables and may be contained with a sauce or starchy structure, the Multiple Puncture Probe may be preferable, whereby the irregular sample can be tested within the jar.

Mechanical damage

Mechanical damage

Seeds of low moisture content handled in bulk, such as soya beans and corn, are often subjected to conditions in storage and transport that result in kernel breakage, which is of substantial concern to agricultural engineers. Factors affecting the susceptibility to breakage as well as equipment to quantify it continue to be researched.

The susceptibility to breakage of soya beans can be measured using multiple methods, such as penetration, bulk shear or compression. In each case, a bean sample is particularly prone to breakage if its fracture force and distance, or area under the force-distance graph, are low.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

No comments:

Post a Comment