When a food product is stored, its texture will change in any number of ways, almost always decreasing the product’s quality.

A high shelf life is useful in the eyes of the manufacturer, and understanding the processes behind food degradation in storage is key to improving this shelf life, where possible.

Texture has its roots in the structure of food, from the molecular to macroscopic levels, and understanding the changes to the food on each of these levels helps to explain the texture changes that occur during storage.

These changes are generally caused by changes in moisture, reactions in food polymers (which can lead to crosslinking or toughening), or by enzyme action. Enzyme action can be beneficial (ripening of meat, cheese and fruit), or unfavourable (spoilage of fruit). The changes caused by moisture variations depend on the initial moisture level in the food sample, and so on its textural properties. Moisture can be gained, lost or move throughout the food’s structure.

Texture has its roots in the structure of food, from the molecular to macroscopic levels, and understanding the changes to the food on each of these levels helps to explain the texture changes that occur during storage.

These changes are generally caused by changes in moisture, reactions in food polymers (which can lead to crosslinking or toughening), or by enzyme action. Enzyme action can be beneficial (ripening of meat, cheese and fruit), or unfavourable (spoilage of fruit). The changes caused by moisture variations depend on the initial moisture level in the food sample, and so on its textural properties. Moisture can be gained, lost or move throughout the food’s structure.

- If a low moisture food, such as a cracker, gains water, crispness will be lost and toughness will develop. These changes can cause the food to become soggy.

- If a high moisture food, such as a carrot, loses water, its juiciness and crispness will be lost, and the food will become flaccid.

- If a medium moisture food, such as sponge cake, loses water, it will become dry. When it is bitten, moisture will move from the mouth to the sample rather than the other way round.

- Rearrangement of moisture takes place in complex food systems such as bread.

Fruit

Fruit is highly valued for its fibre, vitamins and appealing sensory properties such taste, texture, colour and aroma. The texture of a fruit is determined by the structure and chemistry of its nutrient-rich flesh tissue, the parenchyma. When a piece of fruit is bitten into, this tissue breaks down easily to expel its water-based contents, and it is this bursting action that gives fruit its desirable texture.

Generally, the flesh cells of fruit have a thin primary cell wall. In this wall, cellulose provides rigidity and resistance to tearing, and pectic substances give plasticity and the ability for the wall to stretch. Flesh tissue is rigid due to the turgor pressure exerted by the water-based cell contents against the wall, keeping it under tension. The turgidity of the cell is important as it provides crispness to the fruit. The cell wall’s mechanical strength also has a part to play in the rigidity of flesh tissue.

When fruit ripens and deteriorates (undergoes senescence), the most important textural change is tissue softening, which is caused by structural alterations in the middle lamella (a layer that cements the cell walls of two adjoining cells together) and the primary cell wall. This occurs due to enzymatic degradation and solubilisation of pectic materials.

Ripening and senescence happen by three main processes:

- Cell walls weaken - the intermolecular bonds in cell wall polymers break down

- Intercellular adhesion reduces – the middle lamella is degraded by enzymes and the adjacent cells separate, causing tissue softening and loss of cohesiveness

- Cell turgor is lost

The softening of different fruits take place over very different time spans, from raspberries that have a storage life of a few days, to apples that can be stored for many months without any noticeable softening taking place. Some fruits, such as apples, have a waxy skin coating, and this can slow moisture loss.

Fresh Fruit

Natural Causes of Ripening and Senescence

Depending on the type of fruit and its age relative to its lifecycle, storage can cause either useful or harmful changes to fresh fruit’s texture.

- Fruit that is resistant to mechanical stress and still firm when ripe does not generally have any textural benefit from being stored, although a small amount of softening may make the fruit more appealing in some cases, e.g. apples. These fruits change from firm, crisp, juicy and cellular when ripe to flabby, dry and non-cellular when overripe.

- Fruit that softens a large amount during ripening has a shorter storage life. Storage in a controlled atmosphere can delay the onset of ripening in some cases, e.g. pears. These fruits change from soft but yielding, juicy and pulpy, and forming a pulpy bolus in the mouth when ripe to excessively soft, watery (sometimes dry) and providing no resistance to biting when overripe.

- Delicate fruit that is easily damaged by mechanical stress is harvested when the fruit is mature, but not yet ripe, e.g. strawberries. Ripening is designed to take place during storage, and so storage can be said to be beneficial to the texture of these samples. However, their storage life is often short, as they move quickly from ripe (soft texture) to overripe (mushy texture)

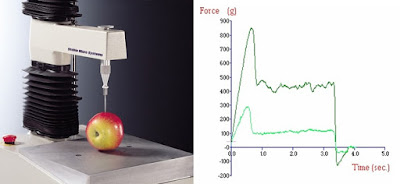

The freshness and general quality of many fresh fruits can be measured using a penetration test. For example, a 2mm cylinder probe penetration into a grape can provide two important measurements – the force and distance to bioyield. As the probe begins to penetrate, the sample deforms under the applied force but there is no puncturing of tissues. This stage ends abruptly when the probe punctures through the skin and begins to penetrate into the sample flesh, often called the bioyield point. The force profile after this point signifies penetration into the underlying flesh of the fruit and indicates that this is substantially softer than the skin. For a harder sample such as an apple, the plateau phase after the bioyield point may be more pronounced and so it is easier to measure the underlying flesh firmness of the fruit by calculating the mean force of the plateau.

In some cases, a cutting test can be more useful. For example, in the peach industry, firmness is measured using a cutting test on peach wedges with a Blade Set or Light Knife Blade. Peaches are not well-suited to puncture tests as a puncture test picks up too much of a peach's spot-to-spot firmn

ess variability. Additionally, newly harvested peaches can be extremely firm, so a bulk testing method such as using a Kramer shear cell is not possible on single column instruments, with forces easily exceeding 100 kg. With the use of a blade set and a Repeat Until Count test, a large number of wedge samples can be tested in quick succession within the same test run.

ess variability. Additionally, newly harvested peaches can be extremely firm, so a bulk testing method such as using a Kramer shear cell is not possible on single column instruments, with forces easily exceeding 100 kg. With the use of a blade set and a Repeat Until Count test, a large number of wedge samples can be tested in quick succession within the same test run.Mechanical Damage Causing Textural Damage

Stresses and strains imposed on fruit during storage and transport have adverse effects on their texture. Bulk storage puts fruit into slow compression for a long time period, whereas impact loading can occur if it is dropped. This damage can be reduced with improved handling procedures and packaging. A package should cushion the fruit and absorb most of the mechanical energy that injures the fruit. Normal stress can cause cleavage in fruit, whereas shear stress tends to cause bruising. This is caused by cells bursting when shear stress exceeds their mechanical (yield) strength.

Any given fruit will have different resistance to both types of stress depending on its stage in ripening.

The following are three examples of mechanical damage:

Impact damage is traditionally measured by dropping fruit samples onto a hard surface and making an estimate of bruise volume, or by impacting the fruit with a pendulum. The extent of discolouration is also studied.

Alternatively, the bruising potential of fruit such as apples can be measured using continual static compression in a Texture Analyser, to mimic storage conditions. A 75mm compression platen is used to press into the surface of a whole apple. Initially, the sample deforms under the applied force but there is no apparent breakdown of the product.

Stresses and strains imposed on fruit during storage and transport have adverse effects on their texture. Bulk storage puts fruit into slow compression for a long time period, whereas impact loading can occur if it is dropped. This damage can be reduced with improved handling procedures and packaging. A package should cushion the fruit and absorb most of the mechanical energy that injures the fruit. Normal stress can cause cleavage in fruit, whereas shear stress tends to cause bruising. This is caused by cells bursting when shear stress exceeds their mechanical (yield) strength.

Any given fruit will have different resistance to both types of stress depending on its stage in ripening.

The following are three examples of mechanical damage:

- Apples: visible bruising

- Oranges: internal injury, causing rupture

- Peaches: tear lines from impact bruises, or browning and fibre tearing next to the pit after compression forces

Impact damage is traditionally measured by dropping fruit samples onto a hard surface and making an estimate of bruise volume, or by impacting the fruit with a pendulum. The extent of discolouration is also studied.

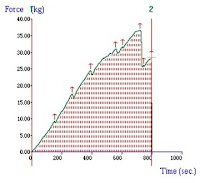

Alternatively, the bruising potential of fruit such as apples can be measured using continual static compression in a Texture Analyser, to mimic storage conditions. A 75mm compression platen is used to press into the surface of a whole apple. Initially, the sample deforms under the applied force but there is no apparent breakdown of the product.

As the compression distance increases, small peaks are seen on the graph profile, each peak indicating a compressive failure of the sample which contributes to the formation of a bruise. This stage ends abruptly when the sample splits or cracks and is indicated by a large decrease in force. The greater the distance that this occurs, the greater is the ability to withstand compression without sample breakage. After the test, the apple can be inspected and the bruise volume estimated.

It is usually desired that, whilst being ripe, the fruit still maintains a high degree of mechanical strength to protect the fruit from damage, such as bruising, during transport and handling. The level of damage suffered by the crop during harvesting and handling can considerably affect its marketable life.

Bruise volume is related to energy absorbed on impact. This can be reduced by improving packaging to absorb more energy, rather than the fruit absorbing it.

Preserved Fruit

Fruit is most often preserved by freezing, drying and canning.

Drying

Dried fruits have a moisture content of 23-26%. Examples include raisins, figs, dates and sliced apples, pears and apricots. The process used to make dried fruit involves slow moisture removal, causing the collapse of cellular structure. The texture of the final product is pliable, cohesive, chewy and adhesive. There is no crispness, fracturability or juiciness.

Many dried fruits are suited to a cutting test. This can be quickly and repeatably carried out using an Extended Craft Knife. Its wide, thin blade enables precision cutting of very small samples without compression if a sample is soft, as is often the case with dried fruit. The maximum force under the curve is recorded as the sample’s hardness, whereas the area under the curve gives a measurement of the work of cutting.

On the other hand, dehydrated fruits have a moisture content of 2.5-3.5%. Examples include apples and pears. They are often produced by freeze-drying, which involves quick moisture removal by sublimation of ice, avoiding the collapse of the cellular structure. This produces a product with an open, porous, firm and dry-crisp texture.

An Ottawa Cell test is well-suited to the assessment of crispness in dehydrated fruit. In particular, these products are often sold for their crispness, which can deteriorate quickly if their packaging is not designed correctly. A test for crispness can be carried out periodically over the product’s expected storage life to assess the time it takes for staling to occur, how quickly and to what extent the desirable textural properties degrade. The area under the curve gives the work of compression and linear distance gives a crispness measurement, which is reinforced by performing a peak count.

Canning

Canning uses heat processing and so the resulting texture resembles cooked fruit due to a disintegrated cell structure and resultant softening. Fruits with more delicate cells and thinner, weaker cell walls will see more textural damage on canning, e.g. strawberries. Treatment with calcium before canning can help strengthen cell walls and preserve texture to some extent, depending on the type of fruit in question.

A bulk measurement is a simple way to assess the textural effects of canning on fresh fruit, and this can be performed using a fixture such as the Ottawa cell. For example, bulk compression of strawberries shows a distinct difference in properties between fresh and canned. Fresh strawberries give a higher maximum force and work of extrusion (area under the curve) as their cellular structure is intact and is able to resist compression from the Ottawa cell plunger.

Freezing

Freezing preserves more of the original sensory attributes than drying or canning, but it does still degrade the fruit’s texture. This degradation is caused by loss of turgor due to ice formation within and between cells. Freezing disrupts cells and their protective mechanisms. Fruit crispness and firmness are lost when the mechanical strength of the cell wall is lost. This makes the fruit excessively soft. Additionally, loss of integrity in the cell membrane causes cell fluids to seep and drip when the fruit is eaten.

As with canned fruit, a bulk measurement is an excellent way to assess the textural effects of freezing and defrosting on fresh fruit. For example, bulk compression of raspberries shows different properties in fresh and frozen-defrosted samples. Fresh raspberries give a higher maximum force and work of extrusion.

In both canning and freezing, a more delicate structure will be damaged to a larger extent. Blueberries and cranberries suffer less freezing degradation than most fruits as they have a higher solids content and no organised internal structure, whereas strawberries are damaged extensively when frozen and thawed.

Freezing degradation can be reduced by using a rapid freezing rate, low freezing temperature and by adding sugar syrup. The effect is worsened if storage temperatures fluctuate, which can happen during transport or in home freezers.

It is usually desired that, whilst being ripe, the fruit still maintains a high degree of mechanical strength to protect the fruit from damage, such as bruising, during transport and handling. The level of damage suffered by the crop during harvesting and handling can considerably affect its marketable life.

Bruise volume is related to energy absorbed on impact. This can be reduced by improving packaging to absorb more energy, rather than the fruit absorbing it.

Preserved Fruit

Fruit is most often preserved by freezing, drying and canning.

Drying

Dried fruits have a moisture content of 23-26%. Examples include raisins, figs, dates and sliced apples, pears and apricots. The process used to make dried fruit involves slow moisture removal, causing the collapse of cellular structure. The texture of the final product is pliable, cohesive, chewy and adhesive. There is no crispness, fracturability or juiciness.

Many dried fruits are suited to a cutting test. This can be quickly and repeatably carried out using an Extended Craft Knife. Its wide, thin blade enables precision cutting of very small samples without compression if a sample is soft, as is often the case with dried fruit. The maximum force under the curve is recorded as the sample’s hardness, whereas the area under the curve gives a measurement of the work of cutting.

On the other hand, dehydrated fruits have a moisture content of 2.5-3.5%. Examples include apples and pears. They are often produced by freeze-drying, which involves quick moisture removal by sublimation of ice, avoiding the collapse of the cellular structure. This produces a product with an open, porous, firm and dry-crisp texture.

An Ottawa Cell test is well-suited to the assessment of crispness in dehydrated fruit. In particular, these products are often sold for their crispness, which can deteriorate quickly if their packaging is not designed correctly. A test for crispness can be carried out periodically over the product’s expected storage life to assess the time it takes for staling to occur, how quickly and to what extent the desirable textural properties degrade. The area under the curve gives the work of compression and linear distance gives a crispness measurement, which is reinforced by performing a peak count.

Canning

Canning uses heat processing and so the resulting texture resembles cooked fruit due to a disintegrated cell structure and resultant softening. Fruits with more delicate cells and thinner, weaker cell walls will see more textural damage on canning, e.g. strawberries. Treatment with calcium before canning can help strengthen cell walls and preserve texture to some extent, depending on the type of fruit in question.

A bulk measurement is a simple way to assess the textural effects of canning on fresh fruit, and this can be performed using a fixture such as the Ottawa cell. For example, bulk compression of strawberries shows a distinct difference in properties between fresh and canned. Fresh strawberries give a higher maximum force and work of extrusion (area under the curve) as their cellular structure is intact and is able to resist compression from the Ottawa cell plunger.

Freezing

Freezing preserves more of the original sensory attributes than drying or canning, but it does still degrade the fruit’s texture. This degradation is caused by loss of turgor due to ice formation within and between cells. Freezing disrupts cells and their protective mechanisms. Fruit crispness and firmness are lost when the mechanical strength of the cell wall is lost. This makes the fruit excessively soft. Additionally, loss of integrity in the cell membrane causes cell fluids to seep and drip when the fruit is eaten.

As with canned fruit, a bulk measurement is an excellent way to assess the textural effects of freezing and defrosting on fresh fruit. For example, bulk compression of raspberries shows different properties in fresh and frozen-defrosted samples. Fresh raspberries give a higher maximum force and work of extrusion.

In both canning and freezing, a more delicate structure will be damaged to a larger extent. Blueberries and cranberries suffer less freezing degradation than most fruits as they have a higher solids content and no organised internal structure, whereas strawberries are damaged extensively when frozen and thawed.

Freezing degradation can be reduced by using a rapid freezing rate, low freezing temperature and by adding sugar syrup. The effect is worsened if storage temperatures fluctuate, which can happen during transport or in home freezers.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

No comments:

Post a Comment