We eat with our eyes, nose, tongue, and ears, so in order to gain maximum enjoyment and pleasure from our food, all of the sensory attributes must be in harmony.

Once you’ve made your perfect texture product you’ll need to measure its texture and use this result as your ‘gold standard’. From here, you can compare all future batches of product made to assess whether it measures up to the product acceptance band that you have created. If a batch falls out of this acceptance band it is not likely to match the consumer’s expectations of the product and may well affect loyalty and future purchase of that product.

Create a product acceptance band/zone for your ideal texture to measure future product batches against. Seeing your data in this way might help you notice quickly what is an acceptable quality and what is not acceptable. You may also use this to test competitive products to see how they sit texturally against your own gold standard texture.

Create a product acceptance band/zone for your ideal texture to measure future product batches against. Seeing your data in this way might help you notice quickly what is an acceptable quality and what is not acceptable. You may also use this to test competitive products to see how they sit texturally against your own gold standard texture.See how to set this up in Exponent:

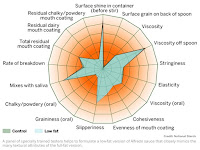

Texture experts Ingredion create texture maps of the sensory eating experiences of their products and (the textures of similar competitive products) like this:

Another way of viewing data is to plot all sensory features of a product in a spider or radar chart. In this example they illustrate just how close they came to reproducing a low-fat formulation when compared with its full-fat counterpart.

These maps could also be built using results obtained from your Texture Analyser to create a full textural story of your products.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments

and equipment from Stable Micro Systems. An extensive portfolio of

specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment