Fresh

fruits are in many ways ideal snacks, but suffer from difficulties in

distribution and lack of universal seasonal availability.

Fresh

fruits are in many ways ideal snacks, but suffer from difficulties in

distribution and lack of universal seasonal availability.Convenience, therefore, dictates that frequently some preparation and preservation needs to be carried out to ensure their availability throughout the year, ensure consistency of quality and even enhancement of particular attributes.

Whilst dried fruits retain a great deal of their nutritive value they often come under criticism for texture as drying can cause considerable loss of textural integrity.

When controlling the textural characteristics of fruit during processing, it is necessary to monitor the condition of the fruit-timing and degree of the breakdown of structure.Dried fruits such as currants, raisins, dates, candied fruit (peels etc.), freeze dried fruits, firm fruit pastes often have a tough and fibrous consistency. They are normally very irregular in shape and highly adhesive although some more recent variations can have an extremely brittle, almost crisp, consistency depending on the method of drying.

Drying of fruit normally needs to be carried out where it is produced and while it is very fresh. There is a great variation in the needs in processing different fruits to achieve the wide variety of purchaser requirements so that practically every fruit that is dried requires different processing cycles. For example, a readily reconstitutable fruit salad may require quite different dried fruits than perhaps the more general specifications of fruit destined for use in a composite fruit snack bar.

|

| Cylinder probe test with confectionery holder |

Monitoring the textural characteristics of this form of fruit highlights the pros and cons of a given drying or packaging choice – get it right, and a dried fruit will deliver all the health benefits and mouth-feel a consumer could wish for. Get it wrong, and the consumer may struggle to separate the fruit from its packaging.

Measuring the texture of dried fruit

|

| Craft knife cutting test |

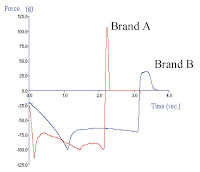

The curve (lower right) shows the comparison of the firmness and stickiness of two brands of dried apricots. Samples are compressed with a 6mm cylinder probe until 100g of resistance is achieved. The time this takes (or the distance moved) to reach 100g indicates the softness/firmness of the sample; a shorter compression distance indicates a firmer sample.

|

| Comparing firmness/stickiness of two types of dried apricots |

The cylinder probe is then withdrawn at maximum speed and the force to withdraw from the product is subsequently

measured; the higher the force the greater is the measurement of stickiness. It is important to hold the sample down during testing to avoid lifting of the sample when the probe withdraws (ideally using the Confectionery Holder, as illustrated in the image of the cylinder probe test above).

Watch the video below to see a summary of the types of testing possibilities that are available for the measurement of fruit and vegetable texture to provide quality control tools and ultimately, consumer satisfaction.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

|  |  |

No comments:

Post a Comment