|

| Kramer Shear Cell |

a: Soft fruits: drupelets and berries – e.g. cranberries, blueberries, blackberry, raspberry, strawberry, pomegranate arils, grapes

b: Fibrous samples: such as pomegranates, citrus fruits, pineapples which have been prepared into pieces.

c: Pieces of fruit that have been prepared into smaller pieces e.g. apple cubes.

The primary issue of these types of samples is that they are usually of varying sizes or are of non-homogeneous nature and therefore make comparisons difficult. They therefore have a high variability from piece to piece within the same batch and require a large sample set to be tested. Puncture or compression tests to rupture are possible but usually produce results with poor repeatability.

Measuring overall firmness of fruits

Obtaining repeatable results when testing by compression testing demands that the dimension of the test piece are constant. To do this, fruit cylinders or cubes therefore need to be prepared which may be impractical in terms of time available or ease of testing. |

| Ottawa Cell |

Bulk testing can be performed either with a Kramer Shear Cell or Ottawa Cell. When using an Ottawa Cell, a chosen number or weight of samples may be placed into an Ottawa Cell containing a holed extrusion plate. Starting at a height of 50mm from the base of the cell, the firmness of the samples are measured by the ease of extrusion of the fruit through the holed plate (held at the bottom of the cell) when force is applied by a plunger to a final position of 10mm above the holed plate.

The plunger compresses the fruit until the structure of the sample is disrupted and it extrudes through the holed outlets. The maximum force and total area under the extrusion curve (“Work of Extrusion”) is obtained and used as an index of textural quality.

Similarly when using a Kramer Shear Cell, pieces are placed into the cell to the same filling volume (number or weight), and the blades positioned at a constant position above the fruit surface. The blades then move down into the sample shearing the bulk to a point close to, or slightly through, the base of the cell.

The maximum force and area under the curve are usually recorded for both of these types of test and taken as an indication of bulk fruit firmness which can be a measure of maturity & ripeness, resilience to processing and handling or conversely, breakdown of structure due to, for example, processing conditions such as canning, or freezing.

Examples of measuring bulk firmness/textural integrity

In recent times, as time and money have become precious, canned and frozen fruit have regained their share of the market as economical and convenient guarantee of daily fruit intake. Unfortunately texture, more than anything, suffers as a result of the canning and freezing process of fruit – the former causes fruit to lose integrity, the latter its crispness upon thawing. Though difficult challenges to overcome, monitoring of fruits at the various process stages can lead to a deeper understanding of textural parameters.

Canned fruits and vegetables retain a great deal of their nutritive value, but such products often come under criticism for their texture. Texture is the most severely affected sensory property during canning and the wholesomeness of the fruit is often rated by the degree to which the fruit maintains its integrity. Texture may be assisted by the addition of firming agents (e.g. calcium chloride) to maintain the physical integrity of vegetable and fruit pieces characteristic of many salsas, chutneys, etc.

|

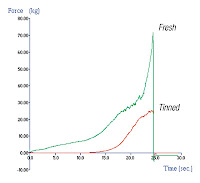

| Fresh vs. Tinned Strawberries tested with an Ottawa Cell |

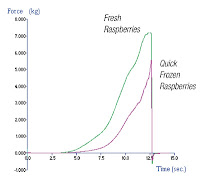

It is generally accepted that fast freezing gives rise to products with better textural properties than slow freezing. While slow freezing promotes formation of large extracellular ice crystals, rapid freezing leads to less cell dehydration and to formation of smaller ice crystals intra- and extra-cellularly, thereby resulting in much less structural damage and higher quality products.

|

| Fresh vs. Frozen Raspberries tested with an Ottawa Cell |

The curves in the graphs above show the comparison of firmness of fresh and frozen raspberries (IQF) and fresh vs. tinned strawberries by a bulk compression test to assess retention of textural integrity. The term 'firmness of fruit' is commonly used to describe a parameter assessed by means of empirical mechanical tests and understood as an attribute that ought to be maintained during storage and processing. In this test, which again involves the use of an Ottawa Cell with a holed extrusion plate, the higher the maximum force and total force to extrude, the higher is the firmness of the fruit which subsequently indicates the overall bite of the sample.

Watch the video below to see a summary of the types of testing possibilities that are available for the measurement of fruit and vegetable texture to provide quality control tools and ultimately, consumer satisfaction:

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

|  |  |

No comments:

Post a Comment