FRACTURABILITY is the tendency of a material

to fracture, crumble, crack, shatter or fail upon the application of a

relatively small amount of force or impact.

It is usually displayed by a product of high degree of hardness and low degree of cohesiveness and is commonly the textural property possessed by baked goods, snacks and generally 'dry' products.

It is usually displayed by a product of high degree of hardness and low degree of cohesiveness and is commonly the textural property possessed by baked goods, snacks and generally 'dry' products.

Fracturability encompasses crumbliness, crispiness, crunchiness and brittleness. A material is brittle if it is liable to fracture when subjected to stress. That is, it has little tendency to deform (or strain) before fracture and usually makes a snapping sound.

Assessing single point fracture

A Three Point Bend test mimics the breaking of the product in half by supporting a bar with guides positioned a suitable distance apart and pushing down centrally with a curved blade from the top. A low force is indicative of a product which requires little effort by the consumer to break whilst the distance at the break point indicates the degree of flexibility, or conversely brittleness, that the product possesses.

Another single point fracture device is the Crisp Fracture Support Rig which is used to measure the fracturability of snack foods and potato crisps (known in some countries as chips) by means of a penetration test. It allows quick location and alignment of the sample over a circular support.

A spherical probe then moved down onto the sample up to the point of fracture. Normally a batch of 12 crisps is individually tested and the averages of the 12 maximum peak force and distance at break/fracture values are calculated to give a measure of fracturability.

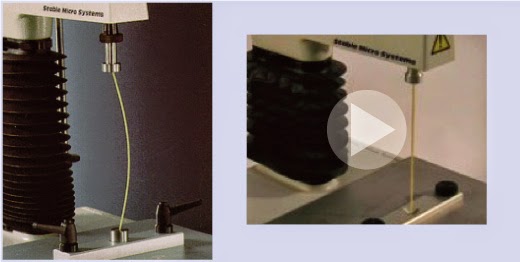

The Spaghetti

Flexure Rig uses another approach to measuring the force of a product to

fracture. The test sample is located

between upper and lower supports in centrally located holes. The upper support is directly connected to

the loadcell and the lower support to the base of the texture analyser. This test investigates the possible inherent

weakness of the dried spaghetti stick which may be due to sprout damage of the

durum wheat or incorrect drying procedures. The measurements give a good indication of the suitability of the

product for packaging and transportation.

The most widely used method for characterising tablet properties is the diametral crushing test where the force required to cause tablet failure by compressing the tablet on its side is measured. This diametral crush test is widely used both for in-process monitoring and quality assurance testing at the end of production.

Fracture (of which effectively the property of crispness is as a result) itself represents a very difficult characteristic to measure, due to the face that a fracture event never occurs identically a second time.

A convenient physical test is therefore to compress a population of multi-particulate products constrained within a container such as the Ottawa Cell. In such a test, a multi-peak jagged curve is obtained resulting from the fracture of a number of flakes/pieces, each peak corresponding to the rupture of a single flake/piece. This is different from the situation where a single piece of sample is being compressed.

However, it offers an averaging effect tests of a more representative portion of the sample which is much more repeatable. The multi peak curves obtained may then be analysed using special calculations within Exponent software.

Trying to detect the different between a coating and a product’s

interior structure

Food coatings and coextrusion methods result in

a wide variety of dual or multi-phase products. Chewing gum tablets, wafers and layered biscuits are typical examples of

food products which may be comprised of a crispy/crunchy exterior shell

enclosing a soft viscous filler material of a different texture. Inherent differences in the physical state

and compositions of the phases offer interesting textural variation to the

consumer. Using a 2mm cylinder, needle probe or craft knife the assessment of

these often fracturable coatings can be detected and differentiated from their

softer interior due to their small surface area and sharpness allowing sample

entry without compression.

Looking at

the fracturability of multi-layer products

Similarly the craft knife is suitable for the measurement of multi-layer products where sharpness provides the ability to measure the force to fracture through the layers which would be impossible to measure with standard blades due to their compressive action on fragile samples.

Similarly the craft knife is suitable for the measurement of multi-layer products where sharpness provides the ability to measure the force to fracture through the layers which would be impossible to measure with standard blades due to their compressive action on fragile samples.

Fixtures designed for a specific product:

Manufacturers of ice cream cones need to consider the role of structural strength in the safe handling, shipping and distribution of cones. A cone strength test measures the force required to cause breakage by simulating the stress imposed when ice cream is pressed into the cone. The resulting graph highlights any weaknesses and consequent need to review ingredient proportions, formulation or cone shape and dimensions.

Measuring the ‘noise’ created when fracture occurs – the Acoustic

Envelope Detector

The Acoustic Envelope Detector can by employed for any material which produces an audible noise when tested as it captures another dimension (i.e. sound) during the test which can also be analysed and used as a measured product feature. This is usually applied to brittle materials and the acoustic signal is as a result of a crack, break, snap or failure of some type.

The Acoustic Envelope Detector can by employed for any material which produces an audible noise when tested as it captures another dimension (i.e. sound) during the test which can also be analysed and used as a measured product feature. This is usually applied to brittle materials and the acoustic signal is as a result of a crack, break, snap or failure of some type.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment