RUPTURE FORCE – the force that is required to produce a major break/rupture in a

sample – can be related to the firmness and brittleness of a product. It

is related to burst force – the force causing a sample to break

suddenly and violently into pieces. Rupture force measurement can be

crucial for such products as medical implants, which may be required to

resemble soft tissue but must remain intact for the duration of their

intended residence.

RUPTURE FORCE – the force that is required to produce a major break/rupture in a

sample – can be related to the firmness and brittleness of a product. It

is related to burst force – the force causing a sample to break

suddenly and violently into pieces. Rupture force measurement can be

crucial for such products as medical implants, which may be required to

resemble soft tissue but must remain intact for the duration of their

intended residence. Several other products, such as gel capsules containing vitamins, possess bursting as a desirable property, but must withstand transport and handling before ultimately bursting in the mouth.

Typical Methods & Fixtures for Rupture Force Measurement in action:

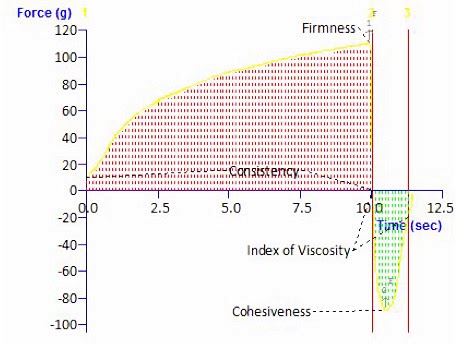

Typical physical properties that can be obtained from a texture analysis graph:

Work of failure, rupture force, rupture strength, brittleness, elasticity.

A wide range of attachments is available for measuring texture analysis properties.

|

| Typical Texture Analyser graph with annotated properties |

We can of course design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific texture measurement.

Once your measurement is performed our expertise in its graphical interpretation is unparalleled – no-one understands texture analysis like we do. Not only can we develop the most suitable and accurate method for the testing of your sample but we can prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information, please visit the Texture Analysis Properties section on our website.

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment