EXTRUDABILITY is the power required to push or force something out of something.

EXTRUDABILITY is the power required to push or force something out of something. A compression-extrusion test consists of applying force to a product until it flows through an outlet (or number of outlets) that may be in the form of one or more slots or holes that are in the test cell. The product is compressed until the structure of the product is disrupted and it extrudes through these outlets.

Quantifying extrudability is important to determine the ease of removal and application of products such as ointments, creams, gels, sauces, paint, icings etc. Product developers can analyse changes in a product's consistency throughout its shelf life and adapt formulations accordingly whilst also enabling manufacturers to assess the suitability of packaging material and its construction.

Typical Methods & Fixtures for Extrudability Measurement in action:

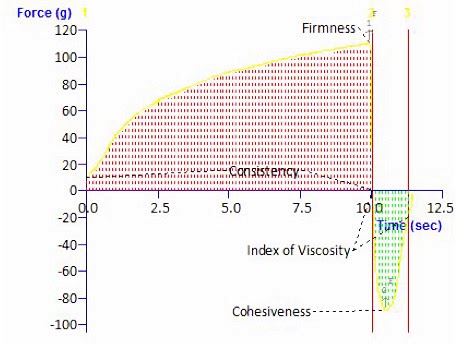

Typical physical properties that can be obtained from a texture analysis graph:

Mean extrusion force which indicates firmness/consistency, homogeneity, removal force, cohesiveness, index of viscosity.

A wide range of attachments is available for measuring texture analysis properties.

|

| Typical Texture Analyser graph with annotated properties |

We can of course design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed our expertise in its graphical interpretation is unparalleled – no-one understands texture analysis like we do. Not only can we develop the most suitable and accurate method for the testing of your sample but we can prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment