DISINTEGRATION is the ability to become reduced to components, fragments, or particles.

DISINTEGRATION is the ability to become reduced to components, fragments, or particles. It may be as a result of decay, loss of cohesion, dissolving in liquid or crumbling and is generally associated with shrinkage, loss of height or volume from its original form. It is one of the primary characteristics of bath bombs, fast-disintegrating tablets, whipped creams, foams and mousses.

The Texture Analyser can be used to monitor the change in height of a product from its original height over a period of disintegration or volume/height loss. By tracking the distance required to move to maintain a chosen force the rate of decay can be plotted and calculated to the end point or period of no further change.

Typical Methods & Fixtures for Disintegration Measurement in action:

Large platens and cylinder probes: the types of products described above tend to be low force applications and therefore a more accurate measurement can be made by the use of as large a diameter probe as possible to provide as large a surface area as possible.

The use of a 500g load cell is also recommended for measurement accuracy.

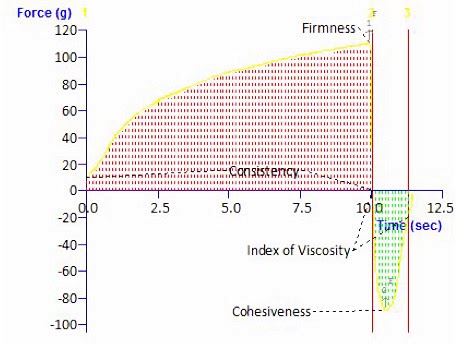

Typical physical properties that can be obtained from a texture analysis graph:

Onset of Disintegration, Initial Swelling Distance (if present), Initial Disintegration Rate and Secondary Disintegration Rate.

A wide range of attachments is available for measuring texture analysis properties.

|

| Typical Texture Analyser graph with annotated properties |

We can of course design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed our expertise in its graphical interpretation is unparalleled – no-one understands texture analysis like we do. Not only can we develop the most suitable and accurate method for the testing of your sample but we can prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment