Food manufacturers constantly strive to keep ahead of consumers. Not only are consumers realising that the world must change how it eats to limit climate change they are forever yearning new sensory experiences. Developments abound in the field of plant-based foods, the use of insects, 3D printing, lab-grown food that look to appeal to consumers newly found moral considerations whilst providing intrigue, novelty and a great back story. With all of these developments there will be the need to assess texture – either to compare with a standard product that has textural expectations or to provide a quality control tool when the final product is mastered. Here are just a few examples of food developments where texture analysis is being featured as a star employee.

The biggest ingredient of future food: Air

As commodity prices rise, food makers must seize the opportunity afforded by air as a product element. Food texture and flavour can be altered with the use of air. Edibles benefit from a light, puffy texture that adds volume, form, size, and appeal, and the use of air allows manufacturers to make larger items with the same number of ingredients, providing consumers a sense of value for money.

Manufacturers' efforts to retexturise foods are being aided by advances in 3D technology, such as selective hot air sintering and melting. Because it can manufacture 3D structures with complicated geometries, complex textures, enhanced nutrition, and realistic flavours, 3D printing is a suitable technology for food manufacturing. According to specialists, 3D printing can be done beautifully with the help of air.

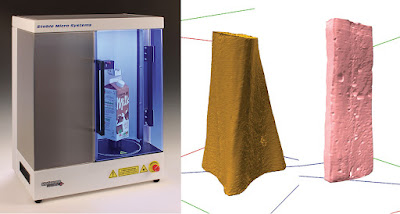

By adding air, not only will the texture need to be assessed, but the volume/density will also need to be measured and monitored. This is where a Volscan Profiler is used, providing a laser-based non-contact method.

|

| Volscan Profiler with typical scans showing a dog bone and nougat |

Read more about air in future foods

Last autumn, Air Protein created meat out of air. This astonishing company has pioneered a process of producing meat using the elements in the air, converting them into nutrients to form Air Protein flour; a complete protein that contains all nine essential amino acids and with an amino acid profile comparable to animal protein.

Solar Foods meanwhile, which has been backed by the Finnish government, aims to have its first industrial facility to produce Solein, its proprietary protein, fully operational by 2023. Solein is a unique single-cell protein born from an equally extraordinary bioprocess of electricity and air. Its fully natural fermentation process is similar to the production of yeast, resulting in the purest and most sustainable protein in the world.

Neutral in taste and appearance, Solein vanishes into your daily meal, while simultaneously maintaining its rich nutritional value. By offering a unified solution that caters to virtually every imaginable meal of today, Solein creates a dazzling world of opportunities for entirely new foods of tomorrow.

Air Protein and Solar Foods methods have their differences, but both produce edible material out of carbon dioxide (CO2). Both use biomass fermentation, leveraging microbes that eat CO2 and other elements of the air, and produce a physical protein that looks similar to flour. That flour can then be used to produce plant-based meats like burgers and meatballs. Sounds futuristic, right? But the fascinating thing, besides the fact that edible-for-humans protein is being created from air, is that Air Protein’s methods are based on methods laid out in a 1967 NASA study on how to grow food on board during long space missions.

Volcanically sourced protein

The air we breathe isn’t the only unusual source of protein.

Nature's Fynd is a food technology firm financed by Bill Gates and Al Gore that produces a protein from a bacterium discovered in Yellowstone's geothermal springs. It is one of the few non-animal sources of full protein since it contains all nine essential amino acids. Dietary fibre, calcium, and vitamins are also included. It's a flexible ingredient that may be used to make meat and dairy substitutes such as breakfast patties and cream cheese, as well as protein drinks and powders.

3D printing microalgae

Fancy having a nutritious meal that is created sustainably from microalgae and printed by a 3D printer?

And then there’s insects

Edible insects are nutritious, easy to farm and have a small carbon footprint, but... Can we stomach the latest emerging food innovations? – BBC News

See how texture analysis can be applied to alternative protein texture measurement

Request our article about Texture Analysis in the Alternative Proteins industry

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplusC texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

|  |  |

No comments:

Post a Comment