Due to the challenging service environment that stents face in vivo, the radial stiffness of a stent is critical to its function of keeping the arteries open and eliminating abrupt closure. Measurements and reporting methods of a stent’s radial stiffness both assist industry in the development of new stent designs and allow regulatory authorities to better evaluate these designs.

In addition the development of a standardised method for radial stiffness and strength assessment may indirectly help to improve understanding of the causes of late stent thrombosis. There is some evidence that this often-fatal coronary event is associated with stent malapposition, which is often the result of insufficient radial stiffness or strength.

Radial

strength and radial stiffness are critical functional attributes in the design

of endovascular devices such as stents, stent grafts, collagen plugs, embolic

filters, and vena cava filters. Testing methods for determining radial strength

and stiffness must provide comparative and quantitative values for modeling the

device interaction with the target treatment site.

Accurate

characterisation and testing of these forces is imperative to the design

verification of endovascular devices. The radial force of endovascular devices

must be adequate to prevent migration of the device and maintain patency of the

lumen, but not so great that it overexpands the vessel or damages it in any

other way.

Many factors influence radial strength and stiffness; a minor change to any of these factors can affect a device’s functionality. Manufacturers must understand the causes and consequences of inappropriate radial stiffness and strength.

Many factors influence radial strength and stiffness; a minor change to any of these factors can affect a device’s functionality. Manufacturers must understand the causes and consequences of inappropriate radial stiffness and strength.

Radial

strength and stiffness are significant values because they help characterise

how well a device will perform its intended function. For example, an embolic

filter is intended to temporarily expand into a vessel lumen downstream of an

area needing intervention, such as an occluded carotid artery. Once it is

expanded, the embolic filter must be seated securely against the vessel wall to

ensure that all blood moves through it and not around it.

The filter’s job is to capture any particles large enough to cause a blockage or a stroke. If an embolic filter does not have enough radial strength, then blood will flow around it and it may not capture all of the large-sized particles. Similar to an embolic filter, a stent must have enough radial strength to hold open a vessel and maintain its deployed position.

A stent, however, is a permanent implant. It must maintain its radial strength over time to prevent stent migration, which could leave the patient vulnerable to restenosis or an aneurism. Conversely, a device with too much radial strength or stiffness may overexpand the target vessel, causing the smooth muscle to thin and leave the patient vulnerable to an aneurism.

A TA.XTplus

Texture Analyser is typically employed to compress the stent to a high

deformation distance at a very slow speed (e.g. 0.2mm/s). During this compression the force is

shown to gradually increase as compression continues.

A TA.XTplus

Texture Analyser is typically employed to compress the stent to a high

deformation distance at a very slow speed (e.g. 0.2mm/s). During this compression the force is

shown to gradually increase as compression continues.

The filter’s job is to capture any particles large enough to cause a blockage or a stroke. If an embolic filter does not have enough radial strength, then blood will flow around it and it may not capture all of the large-sized particles. Similar to an embolic filter, a stent must have enough radial strength to hold open a vessel and maintain its deployed position.

A stent, however, is a permanent implant. It must maintain its radial strength over time to prevent stent migration, which could leave the patient vulnerable to restenosis or an aneurism. Conversely, a device with too much radial strength or stiffness may overexpand the target vessel, causing the smooth muscle to thin and leave the patient vulnerable to an aneurism.

A TA.XTplus

Texture Analyser is typically employed to compress the stent to a high

deformation distance at a very slow speed (e.g. 0.2mm/s). During this compression the force is

shown to gradually increase as compression continues.

A TA.XTplus

Texture Analyser is typically employed to compress the stent to a high

deformation distance at a very slow speed (e.g. 0.2mm/s). During this compression the force is

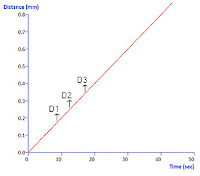

shown to gradually increase as compression continues. After a trigger force of 3g is attained the probe then proceeds to compress the sample to 4.3mm. During this compression the force is shown to gradually increase as compression continues. The distances at 3 force values are recorded as measures of increasing stiffness (see graph below).

Factors that affect Radial Strength and Stiffness

The overall

structural design of the device plays the largest role in a device’s radial

strength and stiffness. In general, devices with very open structures (or low

material-per-square-inch ratios) have less radial stiffness and strength than

more-closed structures (or high material density). Strut thickness also affects

radial strength and stiffness. A thicker strut provides greater radial strength

and stiffness compared with a device that has a thinner strut.

The

material of the device also plays a large role in its radial strength and

stiffness; material selection can make up for an open structure of the device

by providing increased radial stiffness. For example, some cobalt chromium

alloys provide greater radial strength than stainless steel. Therefore, an open

cobalt-chromium stent may provide greater radial stiffness and strength than a

closed stainless-steel stent.

Secondary

processes of a device material also influence radial strength and radial

stiffness. Heat treating, annealing, and polishing are common secondary

processes. Heat treating of the raw material prior to cutting the stent hardens

the material and affects strength and stiffness.

The

annealing process softens the material and allows the stent to expand without

breaking. If the material is overannealed, the stent will be too soft and will

have insufficient radial strength and stiffness.

The common parameters in annealing are temperature, length of cooling time, and position of the material. The length and temperature affect how soft the material is after annealing, and the position of the material affects the uniformity of the material properties.

The common parameters in annealing are temperature, length of cooling time, and position of the material. The length and temperature affect how soft the material is after annealing, and the position of the material affects the uniformity of the material properties.

The method

of polishing devices, such as electropolishing, also affects the radial

strength and stiffness of the device by disrupting the material surface.

For

shape-memory alloys such as nitinol, these secondary processes can be varied to

give the same material different final properties. The elastic range or

softness of a stent can be increased to impart improved flexibility, which

improves deliverability while maintaining adequate radial strength and

stiffness. The secondary processing of shape memory alloys gives the material

its transition temperature (the temperature at which a stent exhibits its

optimal radial strength and stiffness). This temperature can be set at normal

body temperature (37°C).

When

looking at other stent materials under development, such as polymers, more of

the radial strength and stiffness is dependent on the material blend and how

quickly the materials bioabsorb. Having a strong understanding of how each of

these factors affect radial strength and stiffness enables faster device

development tailored to specific vessel types.

We can design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed, our expertise in its graphical interpretation is unparalleled. Not only can we develop the most suitable and accurate method for the testing of your sample, but we can also prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

|

No comments:

Post a Comment