SEAL STRENGTH is the ability to resist forces that can separate materials that have been sealed together.

SEAL STRENGTH is the ability to resist forces that can separate materials that have been sealed together. It may be a flexible surface from a rigid surface or another flexible surface.

Seal strength tests are useful for a variety of products and can be performed on containers such as trays and packaging pouches as well as assessment of adhesive, cosmetic and medical products such as surgical pouches and sterile packaging.

The most common tests are the T-peel, 90 degree peel and the 180 degree peel but different peeling angles are possible. Usually the average force per unit width and the peak force required to separate either of these two surfaces is measured.

The most common tests are the T-peel, 90 degree peel and the 180 degree peel but different peeling angles are possible. Usually the average force per unit width and the peak force required to separate either of these two surfaces is measured.Typical Methods & Fixtures for Seal Strength Measurement in action:

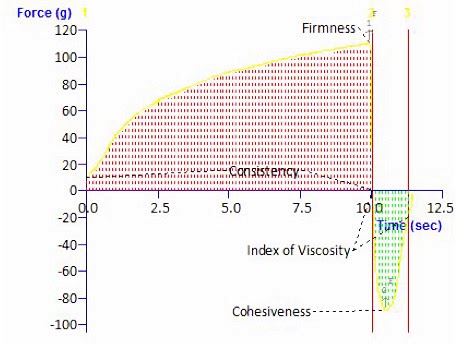

Typical physical properties that can be obtained from a texture analysis graph:

Seal Strength, Initial Seal Break Force, Maximum and Minimum Seal Strength Forces

A wide range of attachments is available for measuring texture analysis properties.

|

| Typical Texture Analyser graph with annotated properties |

We can of course design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed our expertise in its graphical interpretation is unparalleled – no-one understands texture analysis like we do. Not only can we develop the most suitable and accurate method for the testing of your sample but we can prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment