SYRINGEABILITY can be described as the ability of a product to be successfully administered by a syringe and appropriate needle.

Syringes are used in hospitals, surgeries and homes around the world on a daily basis, and for a multitude of purposes. Successful administration, as well as comfortable receipt of the material under the skin, rely on the effective tracking of the syringe piston within its outer tube.

By testing the ease with which an injectable solution is expressed, manufacturers are able to optimise usability and patient comfort, while guaranteeing quality control and product safety.

Manufacturers can also determine the force required to remove the plunger from the syringe, thus emulating the ease with which the syringe piston is withdrawn.

Typical Methods & Fixtures for Syringeability Measurement in action:

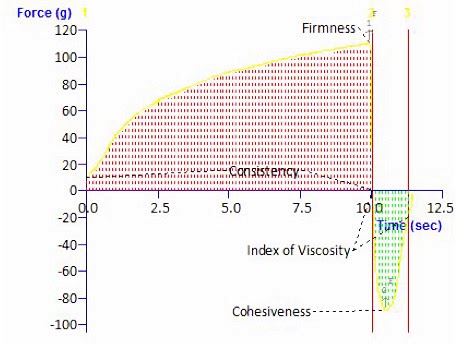

Typical physical properties that can be obtained from a texture analysis graph:

Stiction, Extraction & Aspiration force, end constraints.

A wide range of attachments is available for measuring texture analysis properties.

|

| Typical Texture Analyser graph with annotated properties |

We can of course design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed our expertise in its graphical interpretation is unparalleled – no-one understands texture analysis like we do. Not only can we develop the most suitable and accurate method for the testing of your sample but we can prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment