Compression tests can be carried out on a wide variety of products that experience such a force in natural conditions.

Compression tests can be carried out on a wide variety of products that experience such a force in natural conditions. These may include fruit and vegetables, puffed cereals, cakes and biscuits, confectionery and pharmaceuticals.

Normally, as these products may be oddly shaped, a compressive test is the most reliable way of assessing their fracture behaviour.

There

are several ways of performing a compression test, but the simplest and

most reliable is uniaxial compression. In this type of test a specimen

is squashed between two parallel surfaces until it fractures.

There

are several ways of performing a compression test, but the simplest and

most reliable is uniaxial compression. In this type of test a specimen

is squashed between two parallel surfaces until it fractures. Such a test measures its compressive stiffness, compressive yield stress, strength and strain, energy to start and propagate a crack and fracture toughness (only if the crack area can be measured).

If specimens come in varying sizes and geometries such as fruit and vegetables, it is best to cut out a number of geometrically reproducible specimens from its flesh, e.g. cylinders using a cork borer. This way the variations in the mechanical properties due to size and shape differences are eliminated.

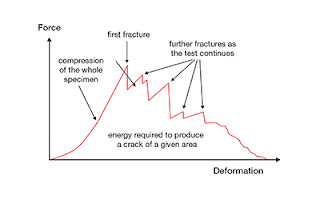

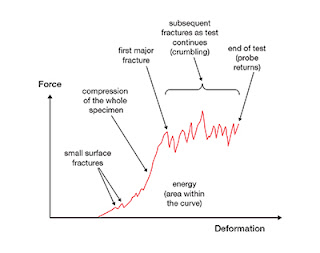

Typical force/deformation plots and measurable fracture properties:

|

| e.g.

Apple (cylinder cut from the flesh) give a plot as shown above. Similar plots are also obtained when testing other crispy fruit and vegetables, chocolate, etc. |

The point of the first major fracture indicates the fracture stress/force and strain/deformation. Stronger specimens break at higher force whereas more pliable ones break at higher deformation. Failure deformation can also be an indication of the moisture content in the specimen.

|

| e.g. Dry cat-food pellets. |

We can design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed, our expertise in its graphical interpretation is unparalleled. Not only can we develop the most suitable and accurate method for the testing of your sample, but we can also prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment