STICKINESS/ADHESIVENESS is the work/force necessary to overcome the attractive forces between the surface of the product and the surface of the material (the probe) with which the product comes in contact.

STICKINESS/ADHESIVENESS is the work/force necessary to overcome the attractive forces between the surface of the product and the surface of the material (the probe) with which the product comes in contact.It is commonly the textural property possessed by confectionery products, cooked pasta products, raw bakery products, pharmaceutical patches and, more obviously – adhesives.

TACKINESS is the property of being cohesive and sticky. It does not appear to be referred to in the food industry, but there are many references in e.g. solder paste measurement for printed circuit board industry.

Stickiness/Adhesiveness is a desirable and sometimes vital characteristic when wishing to stick two surfaces together e.g. for the adherence of coatings, films, attachment of adhesive and medical tapes or drug delivery devices for semi-permanent or permanent applications.

However, it can be an extremely undesirable characteristic in such examples of confectionery wrappers attaching to the enclosed confectionery or chewing gum to shoes, furniture etc. Stickiness is a major problem in the food industry, especially in the baking and confectionery industries, where it can cause considerable difficulty during processing by causing interruptions in production, waste and contamination of machinery.

Sticking

of food to packaging materials is generally regarded as undesirable

resulting in possible packaging material damage, product loss and

disfigurement of the product surface. It can be surmised that the extent

to which this could generate adverse consumer reaction will depend on

the extent of the sticking, on the type and cost of the product and on

the availability of alternative product/packaging combinations.

Sticking

of food to packaging materials is generally regarded as undesirable

resulting in possible packaging material damage, product loss and

disfigurement of the product surface. It can be surmised that the extent

to which this could generate adverse consumer reaction will depend on

the extent of the sticking, on the type and cost of the product and on

the availability of alternative product/packaging combinations.Stickiness can potentially be both a negative and a positive characteristic of foods. It is an expected characteristic of many foods provided that excessively high levels are not reached, for example in soft cookies, toffees and dried fruit and, in some dishes, such as sticky toffee pudding, relatively high levels are required.

Stickiness in foods such as rice can be a positive feature in some cuisines, for example in oriental rice dishes or in Italian risotto, but is regarded as unacceptable in Western cuisine.

In general, however, stickiness finds more usage as a negative term than as a positive term, perhaps reflecting the difficulty in avoiding high levels in some common foods. This can be seen with foods such as rice and pasta, in which even moderate levels of stickiness can reduce product eating quality. This is particularly the case with many sugar confectionery products and with the handling of chocolate products, especially at high ambient temperatures.

Typical Methods & Fixtures for Stickiness/Adhesiveness/Tackiness Measurement in action:

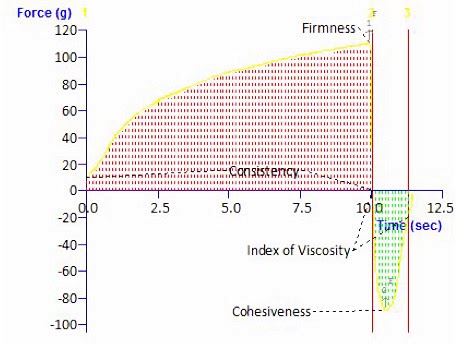

Typical physical properties that can be obtained from a texture analysis graph:

‘Quick Stick’, Surface Stickiness & Stringiness, Work of Adhesion – Energy of Adhesion, Stickiness/Adhesiveness, Cohesiveness, Mucoadhesion.

Testing Considerations

When measuring adhesiveness it is of utmost importance to make sure that the surface of the probe that is used is cleaned thoroughly. Failure to do this will affect the results. The adhesive product must also be held down in some way in order to successfully measure the separation of its surface and that of the contacting probe. The testing probe should not 'lift' the product during the test. As well as the specialist fixtures that have been specifically designed to cope with this issue, simple solutions to this have also been found in literature. Preparing gels on velcro, attaching packaging material to the end of a probe, gluing down the test sample to a disposable surface are all typical examples.

There are many factors that affect the measurement of stickiness such as: test geometry, sample dimensions, probe material, probe dimensions, surface condition, contact force, contact time, separation rate, temperature and sample rheology. It is also commonly known that the probe material substantially affects the results obtained - once a probe is chosen for a test, the material type and surface finish (e.g. polish) should not be changed.

Failure Mechanisms

The formation of an adhesive bond between adhesive and adherend is an essential component of stickiness, but the mode of failure on separation is also of great importance. True adhesive failure occurs if there is a clean failure of the bond between adhesive and adherend, with no residual adhesive remaining on the adherend surface. If adhesive does remain on the surface, cohesive failure within the adhesive has occurred.

A wide range of attachments is available for measuring texture analysis properties.

|

| Typical Texture Analyser graph with annotated properties |

We can of course design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed our expertise in its graphical interpretation is unparalleled – no-one understands texture analysis like we do. Not only can we develop the most suitable and accurate method for the testing of your sample but we can prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment