SWELLING is associated with an increase in size or volume of a product.

SWELLING is associated with an increase in size or volume of a product.Swelling applications include tablets, gels, films, pellets, mucosal tissues, super-absorbent polymers, sponges, aquaculture feed, chemical and yeast leavened products, etc.

Depending on application, swelling can be quantified by measuring changes in force or distance by either (i) compressing a product a slight distance and then measuring how force increases as the product swells, or (ii) applying and maintaining a small force onto the product and measuring the distance change as swelling occurs.

The Texture Analyser can be used to monitor the change in height of a product from its original height over a period of swelling or volume/height increase. By tracking the distance required to move to maintain a chosen force the rate of decay can be plotted and calculated to the end point or period of no further change.

If the product is likely to expand horizontally, then it should be constrained to focus the swelling forces and expansion vertically.

Common questions for swelling applications include: When did the product achieve a certain percentage swelling (10%, 50% or 90%)? How fast does it swell or disintegrate? When did swelling activity end, slow down or diminish? What would happen if more catalyst was introduced at certain times? Among the measurements which can be obtained are: the initial rate of swelling; maximum amount of swelling and length of time to occur and the swelling rate as the product was saturated.

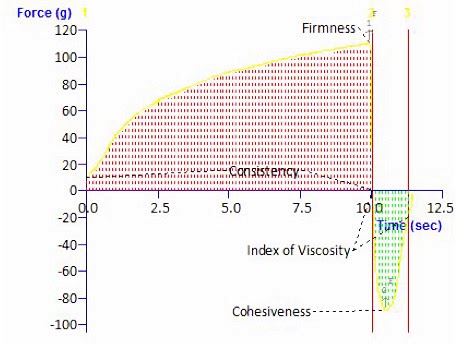

Typical physical properties that can be obtained from a texture analysis graph:

Swelling time, swelling rate, degree of swelling.

A wide range of attachments is available for measuring texture analysis properties.

|

| Typical Texture Analyser graph with annotated properties |

We can of course design and manufacture probes or fixtures for the TA.XTplus texture analyser that are bespoke to your sample and its specific measurement.

Once your measurement is performed our expertise in its graphical interpretation is unparalleled – no-one understands texture analysis like we do. Not only can we develop the most suitable and accurate method for the testing of your sample but we can prepare analysis procedures that obtain the desired parameters from your curve and drop them into a spreadsheet or report designed around your requirements.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

To discuss your specific test requirements click here...

|  |  |

No comments:

Post a Comment