The choice and quality of several key components used in a Texture Analyser will affect the accuracy, precision and resolution of its measurements. Force, displacement and time are the key data channels from which others such as stress and strain are calculated.

When testing a sample, the quality of a measurement is crucial in enabling comparison between batches or within batches over varying time periods. Some measurement methods rely heavily on a high resolution in all data channels.

Force capacity

An immediate limiting factor for testing is load cell capacity. For example, a marshmallow compression test might require a load cell in the range 1 - 5 kg, depending on the intended extent of deformation. A bulk compression test on hard cereal pieces, for example, should use a load cell of capacity in the range 50 - 250 kg. A 10 kg load cell would overload if used to compress bulk cereal pieces. A 250 kg load cell would be capable of measuring a marshmallow compression, but the electronic noise of the load cell and non-linearity in this region may be more evident on the resulting graph.

Load cells with a low force capacity may be used to successfully measure forces as small as a few grams, providing the ability to measure delicate properties such as the puncture force of soft gel samples, although Texture Analysers are not advised for the measurement of samples of very low viscosity unless the method used acts to provide a large mass movement of the sample, increasing the measured force. Load cells of very low capacity (500g) are fragile in nature due to the delicate components required to measure very small forces.

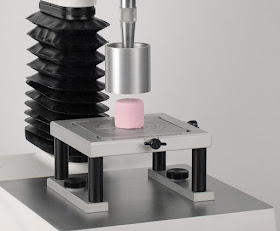

A higher capacity load cell should not be used to measure forces at the lowest end of their working range. For example, a 30 kg load cell would not successfully measure forces of a few grams. The electronic noise present in every load cell scales with its capacity. At some point, when using a load cell of high capacity to measure very small forces, this noise becomes visible on the test graph, and in extreme cases will cause erroneous results. This effect is illustrated below - a typical load cell response.

|

| Example electronic noise levels of a high force load cell and a low force load cell |

Additionally, load cells may have a small non-linear section at the very start of their loading curve so it is advisable to stay away from this region.

As an approximation, load cells should be used to measure forces from around 10% to 100% of their capacity.

The upper limit of load cell capacities available (750kg) generally exceeds the requirements of most food applications but may be required for the testing of packaging, pharmaceutical or adhesive products. Food measurement methods that can expect a higher measured force include bulk compression measurements of hard samples such as animal pellets and breakfast cereals. The forces measured during these tests may be in the region of several kg to several tens of kg, and so higher force load cells are required.At the higher end of a Texture Analyser’s capacity reinforced compression platens and tensile grips are required that will withstand loads of hundreds of kg. Many of the more intricate food-specific rigs will have a force limit an order of magnitude lower than this.

Force sensitivity

Resolution is particularly important when small behavioural differences are used to tell two or more samples apart. For example, this may be the case when monitoring the effect of varying raw ingredient batches of flour in a sponge cake. The firmness of samples in compression may be similar, but small differences indicate inconsistencies in the final product.

Load cell choice is the main determinant of force data quality. The accuracy of the load cell generally varies with applied force, as a percentage of load cell capacity – the error quoted for the load cell is a percentage of the reading. Any offset error in load cells is negated by taring the force, so the zero point should not be affected by an error. Resolution (the smallest force division available for measurement output) is generally provided in grams.

Why not request a Quick test setup guide poster for placement near your instrument to inform users:

Or if you have lost it, request a 167 page (pdf) in-depth manual to be sent to you.

There is a Texture Analysis test for virtually any physical property. Contact Stable Micro Systems today to learn more about our full range of solutions.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplusC Texture Analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is available to measure and analyse the textural properties of a huge range of food products. Our technical experts can also custom design instrument fixtures according to individual specifications.

No-one understands texture analysis like we do!

Get in touch to discuss your specific test requirements

|  |  |

No comments:

Post a Comment